Is user-friendliness possible in complex supply chain planning? Ask Tim

Brenda Rompf - February 10, 2025

Yesterday, I returned home with a big smile on my face, and I have to thank Tim for that. Tim is an operations planner at a process manufacturing company where we’re working to improve service levels. After a full day of hands-on training, he said:

“This is great! People told me that Unison Planning could deal with the most complex supply chains, which made me worry that the system would be too difficult for me to work with. I must say I’m pleasantly surprised about OMP.”

Tim’s enthusiasm confirmed a fundamental part of our vision: Even in the most intricate supply chains, a planning solution must handle complexity while ensuring simplicity and ease of use. After all, low user acceptance is a major reason why digital transformation projects often fail to deliver.

Tailored interfaces for every user

“Now, here’s the million-dollar question: How can a solution for inherently complex problems be easy to use? The answer lies in the word ‘tailor’. ”

Blog post

In the Unison Planning platform, the user interface is tailored to the company’s needs and each user’s specific role.

For example, operations planners like Tim use specific tools and views designed for their tasks, which are different from what demand planners, tactical planners, or managers need.

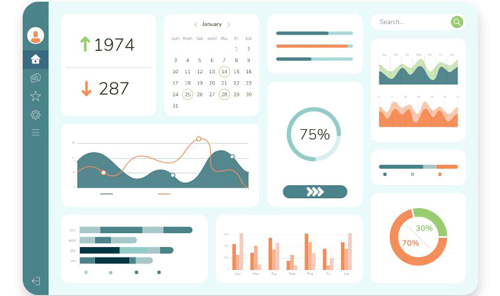

Supply chain managers, on the other hand, benefit from personalized, intelligent dashboard-like overviews that provide an overview of supply chain performance and help them decide on next steps. They can also drill down into details to get a closer view of certain product types, production assets, regions, customer types, or individual customers. The ability to zoom in and zoom out to the desired level of detail or aggregation is built into the system, using maps, graphs, and color schemes to clarify the context.

Blog post

Access to relevant industry- and company-specific features

Blog post

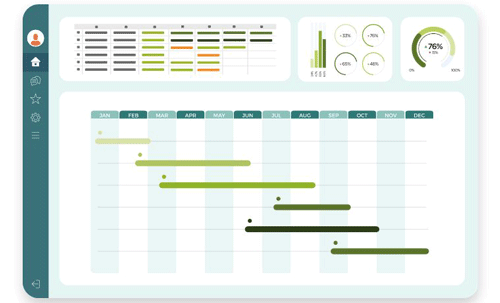

As I said, supply chain planners get more specific views. For example, when finetuning a plan, they get a clear view of the constraints to be met, check if their plan is feasible, and evaluate performance metrics like service level, material cost, safety stocks, machine utilization, and C02 emissions.

The user interface and functionality are tailored to their industry and company. This means that industry- or company-specific features built into Unison Planning will only be available to the planners who need them. Examples include regulatory constraints in the life sciences industry, shelf life constraints in the consumer goods and life sciences industries, throttling in chemicals, routing in metals, and cutting and slitting optimization in paper and packaging.

Blog post

Boosting morale by automating mundane tasks

Automation is a game-changer for planners. Instead of crafting plans from scratch, they start with draft plans automatically generated by AI engines. These engines provide clear explanations of how the results are achieved so that users can understand them and focus on the remaining exceptions.

This exception-based planning improves employee morale by reducing the amount of mundane tasks. Admittedly, some effort is needed to get the automation right, but that is an upfront investment, a collaborative effort of key users and OMP industry experts that clearly pays off.

Focus on the job, not the software

Ultimately, a solid implementation ensures users don’t have to worry about irrelevant or obscure details. We want users to be able to focus on their job, not on the software.

Tim saw the value of all this in our workshop. Thank you, Tim, you made my day.

Whether you’re a business leader or a supply chain planner, we’ve got you covered with tailored solutions. Discover how Unison Planning™ can help you achieve your goals.

Brenda Rompf

Strategic Account Manager at OMP USA

Biography

With over 25 years of experience in customer relationship management and enterprise sales, Brenda oversees strategic accounts at OMP. She is dedicated to driving customer success by fostering innovation, translating needs into actionable solutions, and supporting growth.