Balancing complex trade-offs in chemical supply chains

Chemical supply chains are caught between the uncertainties of global demand and the push effects resulting from the various batch, campaign, and continuous or semicontinuous production flows. Assets must be used to their full potential, waste must be minimized, and margins assured. How can you balance all these challenging trade-offs? OMP is here to help chemicals companies orchestrate demand and supply, maximize asset utilization, and set out the right inventory strategies to boost profitability.

Demand pull challenge

Demand for chemicals is very diverse and includes a broad range of base and intermediate chemicals, as well as a wide variety of specialty products. Base and intermediate chemical production chains create a wide variety of high-value and low-value co-products potentially off-balance with market demand. Businesses have to optimize their use of dedicated and non-dedicated tanks and warehouses all over the world. This has operational implications for loading and unloading too.

Production capacities need to be carefully planned to minimize changeovers, taking into account fixed-wheel and flexible-wheel policies, throttling decisions, co-product fractions, and the actual performance of catalyst installations.

Some businesses will have to optimize utilities consumption based on the variable price of steam and electricity. And decisions have to be made to prioritize certain demands, sell certain volumes on the spot market and reserve others for captive use.

The specialty market has its own challenges. It relies on a mix of make-to-order and make-to-stock production strategies, is subject to stringent quality control processes and involves large networks of subcontractors and distribution channels. The need to carefully tune inventory levels adds to the complexity of it all.

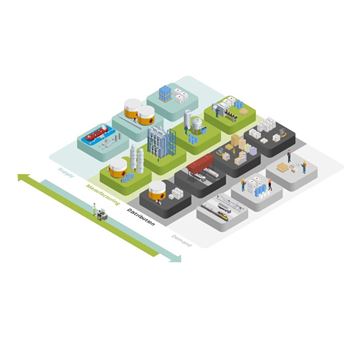

Modeling the entire supply chain

Unison Planning™ takes care of all this. OMP experts understand exactly how your chemical supply chain works and model it with precision. This includes production and storage installations, input and output constraints, and product- and time-dependent rates.

We implement variable bills-of-material to manage co-product fractions, throttling, and recycling opportunities. Batch production processes are modeled too, allowing blends to be managed. We can even model the service levels and constraints of your various contracts and swap deals.

The results

Powerful forecasting techniques, value-driven solvers and scenario planning capabilities connect all ends to help you manage and coordinate your entire chemical supply chain planning solution. With a clear overview of supply and demand you can maximize asset utilization, keep inventory levels within reasonable limits, and reduce waste and costs.

Full end-to-end visibility aligns different departments, makes planning more effective, and boosts overall profitability. Planners, managers and executives across your entire organization will be delighted.

Looking for real business results? Unlock enhanced collaboration and profitability for your organization with Unison Planning™.

A tailored solution

Success stories

What our customers say

“It’s now possible for us to make complete scenarios in a very limited time. We can also make a scenario that is value-based and not volume-based, and this is a really big point in our business.”

David Kochanek, Supply Chain Solution Manager at Evonik Oxeno

“OMP is capable of generating a value-based plan, including the complexities of our chemical network.

We now discuss value instead of volume!”

Rainer Fretzen, Head of Performance Intermediates at Evonik

"Unison Planning™ is the perfect solution to solve our complex requirements in a very dynamic, demand-driven business.”

Stefan Hauenschild, Sales & Operations Planning Responsible at Siegwerk Druckfarben

“The OMP consultants’ depth of knowledge in both the chemical industry’s business processes and the solution’s capabilities contributed greatly to the success of the Unison Planning™ implementation at Eastman.”

Marc Dietrich, IT Planning Team Leader at Eastman

“Unison Planning™ allowed us to integrate our planning and scheduling needs with our corporate SAP platform. OMP has proven the flexibility to support scheduling needs ranging from batch to continuous processes.”

Jim Carey, Supply Chain Manager at Eastman

“The Axalta and OMP teams performed a fantastic job in an extremely short timeframe. With OMP, we jumped to the next generation of end-to-end planning and scheduling solutions. We managed to reach significant inventory reductions and shortened frozen horizons while improving service levels.”

Aaron Weis, Vice President & Chief Information Officer at Axalta