Putting sustainability into practice: How VPK embeds carbon reduction into supply chain decisions

Bart Verbruggen - May 23, 2025

As a firm believer in sustainability, I often emphasize that bold promises are not enough to achieve real impact. It’s much more about action. Major one-off investments can provide the context for substantial sustainability improvements. But what’s often overlooked is the huge potential that arises from consistently making the right decisions at every step of the supply chain.

I’m proud we partner with a long-term customer who shares this belief. VPK Group is a leading packaging group that has grown from a local player into an international supplier of sustainable packaging solutions. Working together, we integrated sustainability at the heart of their supply chain decision-making using OMP’s Green Planning framework.

From theory to everyday impact

Global supply chains account for around 60% of total greenhouse gas emissions, a clear indication of the vast potential everywhere for sustainability improvements through thoughtful supply chain planning. Yet, while sustainability often ranks among their top priorities, too few companies integrate it intensely enough into their operational decision-making.

VPK Group is an exception. Aiming, by 2030, to reduce scope 1 and 2 CO2 emissions by 42% and upstream scope 3 emissions by 52%, the company understands this means more than just one-off investments; it means they have to make daily decision-making much better-informed.

Enter: Green Planning. By activating this powerful OMP framework as part of its Unison Planning™ solution, carbon footprint is now a central factor in VPK’s procurement processes. They can now favor suppliers serious about reducing emissions, making sustainability a concrete daily pursuit giving real results rather than merely a theoretical goal.

Expanding the planning framework

Blog post

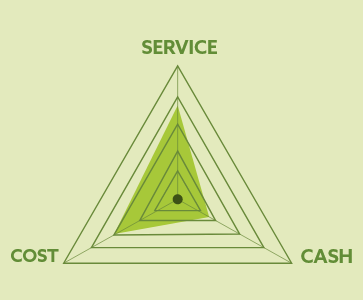

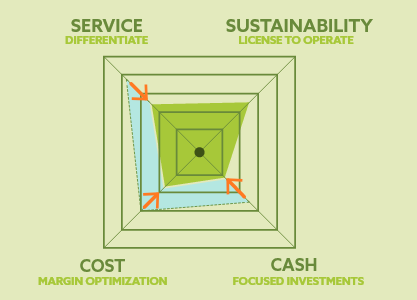

How are they doing this? Well, traditionally, planners aim to balance the supply chain triangle of cost, cash, and service. Sustainability now adds a crucial fourth dimension to the puzzle. While this creates fresh complexities and trade-offs, it also presents significant opportunities for innovation. Some industry watchers are even pronouncing that sustainability is becoming essentially a “license to operate,” and companies not complying with society’s shifting sustainability expectations will make themselves irrelevant.

Contrary to common belief, sustainability doesn't always imply extra costs. Often, companies find significant win-win opportunities, resulting in both financial and environmental gains. VPK is a striking example of how sourcing decisions can improve overall company sustainability without significantly impacting the bottom line. Less waste, lower energy consumption, and more efficient transportation from better supply chain planning are good for the balance sheet and the planet.

Blog post

For its packaging products, for example, the company has to balance production capabilities, logistics, purchase options, costs, and customer demand when deciding whether to source paper internally or through external suppliers. Their proactive commitment to sustainability has added carbon footprint as a decision parameter in this complex supply chain decision-making process.

Internally, emissions data is reliable and independently audited, while FEFCO industry averages help fill external supplier data gaps, with CO₂ intensity penalties where appropriate. As the full case study reveals, this results in a reliable and consistent Green Planning framework, allowing VPK to make better-informed supply chain decisions.

Blog post

Control what you can

You can't control every aspect of your environmental impact, but you can significantly influence it, particularly within your supply chain. Every procurement, transport, and production decision is an opportunity to make a difference.

I love helping companies seize these opportunities without compromising their supply chain performance. By proactively addressing sustainability, reducing unnecessary transportation, optimizing inventory management, improving resource efficiency, and planning product lifecycles more effectively, companies often achieve cost reductions and sustainability improvements.

The first step is creating visibility and clear analytics on future emissions. But real impact comes when planners actively optimize supply chain decisions, including sustainability metrics, making informed trade-offs between environmental impact and traditional KPIs.

With the Green Planning framework, VPK sets emission limits as hard constraints and compares suppliers based not only on price or quality but also on their environmental performance. This approach means smarter, more sustainable decisions that align with strategic business goals.

Real-world results: smarter and more sustainable decision-making

What excites me most is seeing companies like VPK leading by example. They demonstrate that sustainability is more than just good ethics; it's also smart business. By meeting customer and consumer expectations for sustainable solutions, these forward-looking companies secure competitive advantage and contribute meaningfully to a better future.

At OMP, we’re proud to support businesses’ sustainability efforts. Our Green Planning framework integrates supply chain planning excellence with deep industry expertise to provide clear, proven solutions for smarter and more sustainable decisions. VPK's proactive approach shows how everyday decisions can make a significant difference.

Want to dive deeper into VPK’s sustainability journey?

Bart Verbruggen

Commercial Lead Paper, Plastics and Packaging at OMP BE

Biography

20 years at OMP focusing on supply chain excellence in paper & packaging have given Bart a good insight in the industry challenges. He combines business development and advisory to help companies excel in supply chain planning and digital transformation initiatives.