5 supply chain planning trends shaping 2024

Philip Vervloesem - December 21, 2023

Supply chain resilience remains a hot topic for supply chain leaders. With ongoing disruptions testing the stability of global supply chains, managers and planners are constantly seeking innovative solutions to anticipate turmoil and get a better handle on disruptions.

After speaking with experts at Gartner, prospects, customers, and alliance partners, I’ve identified five trends that are on the horizon. Will these game-changing evolutions turn 2024 into a pivotal year where we take supply chain planning to the next level of intelligence and decision-making power?

1. Generative AI will become a trusted companion for planners and managers

Blog post

Generative AI is now finding its place in business applications and is making significant strides in transforming how we plan supply chains. It supports a more conversational interaction with advanced planning solutions. This allows planners to swiftly formulate relevant scenarios to analyze and compare, even in highly intricate situations with lots of conflicting business objectives. Both planners and managers can ask the planning solution to explain a forecast signal, list the most critical issues to review, or perform an optimization.

In 2024, we’ll see more real-life examples of how Gen AI can enhance the user experience in supply chain planning. But even if it doesn’t fully deliver on that promise, the boost Gen AI gives to existing eXplainable AI (XAI) initiatives and planning automation alone makes it a technological evolution worth monitoring.

Blog post

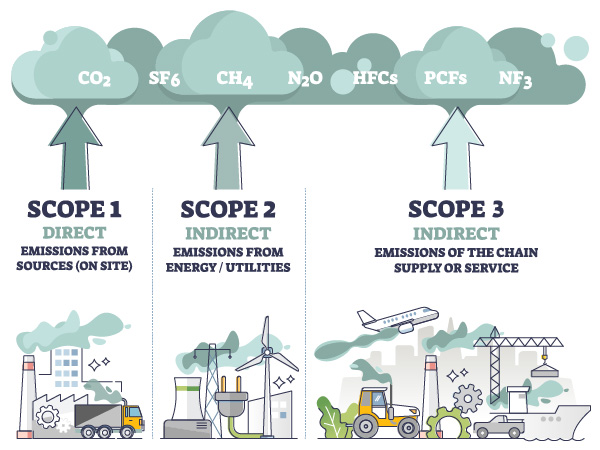

2. Supply chains will embrace Green Planning to reach their ESG goals

Blog post

With the aim of reaching carbon neutrality by 20XX, ESG regulations set a clear deadline for companies to implement comprehensive sustainability programs. This has two major effects. Firstly, it sparks a rush for reporting initiatives, triggering numerous requests for both upstream and downstream Scope 3 data. Secondly, it shifts the focus of boardroom discussions toward sustainable supply chain practices.

2024 is the year to implement Green Planning, which puts environmental, social, and governance (ESG) criteria center-stage in supply chain planning decisions. This planning approach incorporates relevant ‘green’ KPIs and objectives within the supply chain planning digital twin. Companies will need a solid framework to include alternate energy sources, greener materials, sustainable mobility, circularity, and other ESG strategies in the planning process. They will also need to learn how to make green business decisions to optimize for these new KPIs in addition to cost and service level.

Blog post

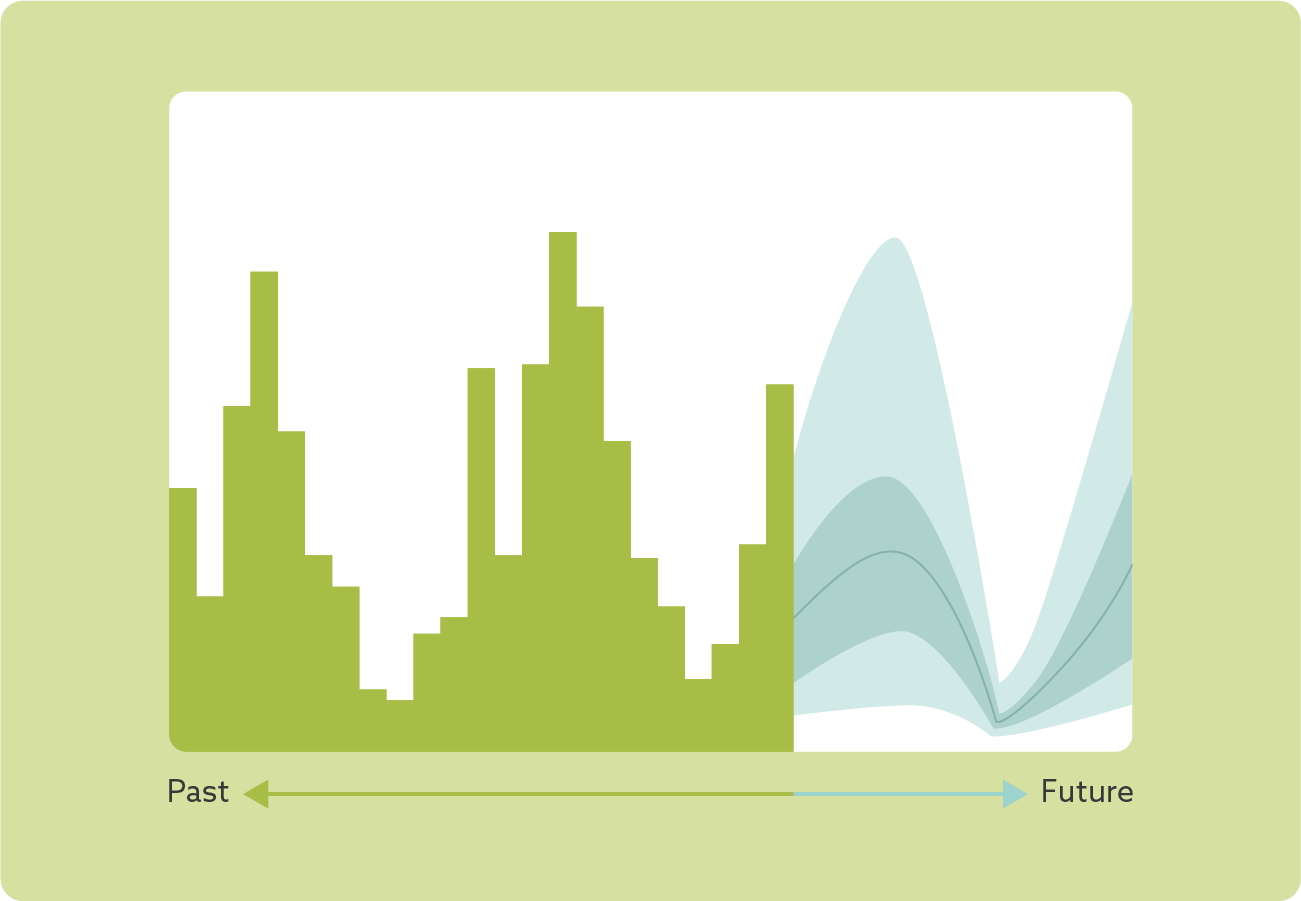

3. Probabilistic planning will help in better preparing for (or avoiding) disruptions

Blog post

Dealing with uncertainty is a crucial skill for supply chain planners. Running different scenarios is their primary instrument to understand how shortages, delays, capacity issues, or market trends might affect their plans. However, as disruptions increase, handling a rapidly increasing number of scenarios becomes challenging. This is where probabilistic planning offers a solution.

Simply put, it means planning for a range of possible values and events instead of focusing on individual scenarios. This approach offers insights into how sensitive the plan is to uncertainties throughout the entire supply chain, covering both demand and supply.

Planners will assess the impact of unfavorable combinations of events more accurately, regardless of their likelihood. They will be able to react faster by using predictive modeling, leveraging outside-in data, and AI and ML techniques.

Blog post

As a result, companies will find it easier to prepare for disruptions. For instance, they can reshape their business strategies and supply chain policies to enhance resilience and minimize the impact of unfavorable situations.

4. Integrating external data will boost market insight

Companies will further explore the potential of external supply and demand data to boost insight into market evolutions. This outside-in approach will reduce the lead time to act on shifting market dynamics, allowing companies to respond more quickly and effectively. This will, in turn, drive forecast accuracy and improved decision-making.

Blog post

For example, external data gathered from sources like social media and point-of-sale can provide insight into actual consumer responses to newly launched products or promotional campaigns. Data will increasingly become an asset and, by leveraging AI capabilities, companies will be able to separate signal from noise, relying less on ‘perfect’ data to get started.

Challenges, highlighted by our own Spark Initiative, include finding, ingesting, and incorporating relevant data, and rethinking planning and decision-making processes. Nonetheless, the potential benefits and the ever-increasing complexity of our supply chains will keep pushing companies to adopt this trend.

Blog post

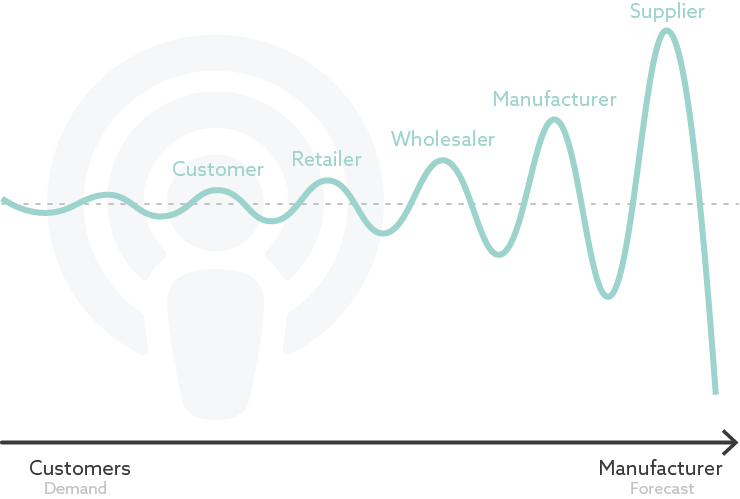

5. Customer-centric decisions will reinforce the need for end-to-end value stream planning

Blog post

The pandemic accelerated a shift in consumer-centric market behaviors, with new business models such as direct-to-consumer entering the market, and gradually finding their way into the most hardcore B2B industries. Never before has the customer been more king.

What does this shift mean for supply chains? Supply chain excellence will increasingly be evaluated against the ability to serve a company’s end consumer or B2B customer. Adopting a customer-centric planning approach entails maintaining a high service level and focusing on factors that drive satisfaction and well-being.

Blog post

Achieving this requires visibility and control over the entire supply chain:

- a near-real-time understanding of market demand

- across a complex network of manufacturing and distribution resources

- including critical raw materials and supply lines.

These elements will confirm the need for an end-to-end planning solution that incorporates all relevant aspects of the supply chain into a unified AI-powered digital twin, providing the required decision intelligence.

As we approach 2024, these trends signify a pivotal moment for supply chain evolution. Embracing these advancements will not only enhance resilience and adaptability but also drive sustainable practices and customer satisfaction, ultimately shaping a more robust and responsive supply chain ecosystem.

Want to discuss how OMP can help you leverage these trends?

Philip Vervloesem

Chief Commercial & Markets Officer at OMP

Biography

With 22 years’ supply chain digital transformation experience in a whole range of industries, Philip currently leads OMP’s business and market development globally while heading up the company’s US operations. Focusing on vision, strategy, and global community building, Philip has a proven history of boundary stretching and thought leadership in supply chain planning innovation, building new markets, and growing and supporting high-performing teams on both sides of the Atlantic.