Inside the Spark Initiative: A journey of supply chain innovation

Paul Delbar - September 19, 2023

The OMP Spark Initiative is in full swing, and as OMP’s Product Marketing Manager, I’ve been fortunate to be a part of this exciting journey.

When we started exploring the benefits of outside-in planning, the learning curve (or should I say, the un-learning curve) seemed quite steep. However, with a group of enthusiastic customers and Lora Cecere guiding us, we have successfully completed the journey. The first results have proved to be nothing short of impressive.

In this blog post, I want to share some key takeaways and reflect on the importance of embracing outside-in planning in the supply chain world.

The key principles of outside-in planning

The Spark Initiative was set up to explore and test “outside-in planning.” This approach challenges traditional supply chain paradigms by focusing on the actual demand as a real-time stream of information as the primary driver of supply chain decisions, rather than relying on derived signals like order or stock replenishment data.

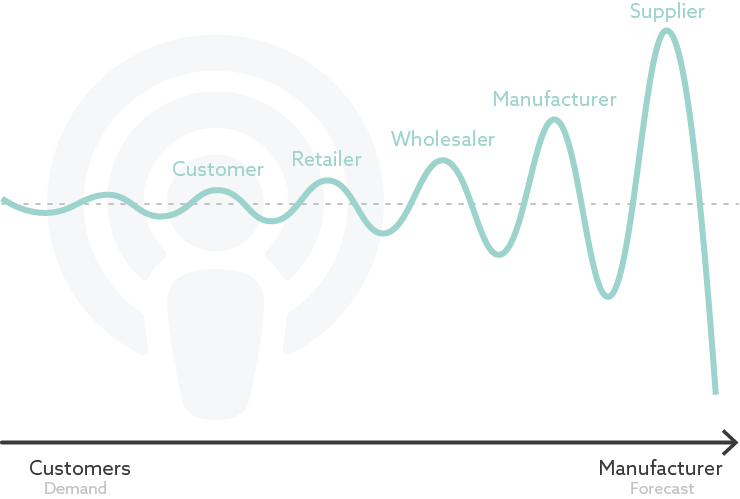

There’s a latency between an end customer picking your product from a shelf (the actual sale) and the outlet issuing a replenishment order. In addition, it takes time to turn that order signal into planning and execution decisions. The delay inherent in waiting for these signals can lead to the dreaded phenomenon known as the bullwhip effect, causing inefficiencies and disruptions throughout the supply chain.

Blog post

Data latency and functional silos

Data latency isn't limited to just one part of the supply chain. It spreads across sales, production, procurement, and suppliers. And it highlights the fundamental flaws in how we structure our supply chains — often as functional silos, each optimizing for different key performance indicators (KPIs). The result is a fragmented system that struggles to respond effectively to the same demand signal drum.

Blog post

Moving toward outside-in planning

But burning down the house is hardly realistic. So, how does a visionary supply chain leader initiate the shift toward outside-in planning? Where do you start, who should be involved, and how can you ensure that the first steps are significant enough to yield results but not too ambitious so you fail? Here are three key challenges:

- Accessing real-time demand data

How do supply chain leaders access and harness actual, real-time customer-of-customer demand data? We’re not just talking about point-of-sales data from retailers, but also data from car sales (as a predictor for paint demand), consumption of pharmaceuticals, raw material buying from industrial manufacturers…

- Finding the most relevant information

Which signal contains the most relevant information, unbiased by buying intentions, hedging, or inventory buffers? If you don't have end-customer sales data, is there something else that can act as a proxy, sacrificing some latency to increased insights into the real demand pattern?

- Translating data into actionable signals

If you have this massive volume of data, how do you translate it into actionable signals (harmonizing across product codes, units of measure, and so on) at scale and in near-real-time?

Fortunately, advancements in technology have made it easier than ever to gather and transform large-scale data. While this increases the importance of collaboration and data sharing, the recent supply chain crisis has shown executives that action is needed now. And for some, that was sufficient reason to join OMP’s Spark Initiative.

Exploring achievable value: from concept to reality

Blog post

OMP’s goal for the Spark Initiative was to unlock more value for its customers by exploring the practical applications of outside-in planning within real supply chains. So, we set sail with the goal of learning, experimenting, and sharing experiences, guided by an expert Advisory Board.

To ensure the success of this endeavor, teams worked on identifying use cases that scored high on two criteria: achievability and potential value.

Blog post

Nestlé and General Mills’ test cases

Nestlé’s test case revolves around new product introductions. Since there’s no prior sales data, the first production run relies on sales and marketing forecasts. But can we accelerate demand visibility to give better guidance for future production runs instead of waiting months to discover if a product is a hit or a dud? In terms of outside-in thinking, this is a situation where latency has a big impact, and reducing it is highly valuable.

General Mills took a different but related approach to reducing latency. The slow transformation of demand signals into supply signals via traditional material requirements planning (MRP) processes leads to providing raw material suppliers with inaccurate and volatile forecasts. From an outside-in perspective, this boils down to synchronization — not only across functional silos, but also across the extended enterprise.

What have we learned?

While you will have to wait until the OMP Conference to discover the detailed insights and results, a glimpse into some of the test cases reveals interesting learnings.

- Break down departmental silos

The most significant lesson learned so far underscores the critical need to break down departmental silos and enhance collaboration. With different teams tackling different questions at different times, it’s hard to speak a common language and set objectives that reinforce one another.

- Reexamine the process model

The planning processes, starting with sales and operations planning (S&OP), need to be reexamined to ensure they promote collaboration rather than siloed thinking. So inevitably, we’re going to review the process model and rethink roles and responsibilities. This becomes evident when we try to gather data. There might be valuable data collected by one team that the other team is unaware of. Relevant data may be perceived as “owned” by one team and consequently withheld from others.

- Embrace agility

For decades, our traditional organizational structures, roles, and processes have been optimized for efficiency, but not necessarily for agility. We may have ended up designing for a steady state which no longer exists. Outside-in planning advocates for a unified perception of the state of the business, driven by demand, enabling all stakeholders to have a simultaneous view of the supply chain and make balanced decisions.

Can you see the Spark?

Blog post

As Spark participants continue to work on these test cases, they’re increasingly convinced of the potential value of outside-in planning. They’re gaining insights into how better collaboration can be achieved and how to introduce these changes at scale.

From my perspective, observing how board members and customers grew from this experience was remarkable. From expressing expectations and undergoing training to testing real-life supply chain scenarios, it was one of the most incredible innovation journeys I’ve been part of. The commitment and enthusiasm of everyone involved were truly inspiring.

Blog post

If you’re curious about their experiences and want to learn more, I encourage you to watch our latest webinar. It offers a peek into the Spark Initiative’s journey, including early insights and key milestones. If you’re joining us for the OMP Conference in Barcelona, you will be among the first to learn about the final results.

Together, we can navigate the winds of change and welcome the future of supply chain management through outside-in planning. Can you see the Spark?

Paul Delbar

Senior Marketing Manager at OMP BE

Biography

Paul spent most of his career in software development, product management and marketing and enjoys using technology to bring solutions to customers. No stranger to supply chain planning and cross-enterprise collaboration, he is always interested in hearing your story and sharing it with the OMP Community.

.png)