Biopharma’s triple threat in 2025: tariffs, price pressure, and FDA cuts

Allen Jacques - July 11, 2025

This year is proving to be one of the most challenging the pharmaceutical industry has faced in recent memory. The warning signs are clear: rising tariffs, pressure on drug pricing, and looming regulatory agency cuts. While each of these factors alone would pose a serious concern, the combined effect could fundamentally reshape the biopharmaceutical landscape.

Tariffs hit where it hurts: supply chains under fire

Blog post

![]()

Disruptions are nothing new, but 2025 will be remembered as the year tariffs hit biopharma where it hurts. For the first time, the U.S. is expected to impose tariffs of up to 25% on imported medicines and active pharmaceutical ingredients (APIs). Historically exempt, biopharmaceuticals are now at the center of a heated geopolitical trade shift. This adds pressure to an already strained industry dealing with low margins and high expectations.

Blog post

Why generics feel the squeeze the most

Blog post

The impact of tariffs isn’t spread evenly. Patent-protected drugs command higher margins, sometimes up to 96% gross profit, and can absorb the extra cost with minimal damage. A 25% tariff might barely move the needle.

Generic drugs, however, are a different story. In an ultra-competitive market with much tighter margins, even a modest tariff-driven cost increase will significantly impact profits. These companies will likely be forced to raise prices, and all of this at the same time, the government has announced intentions to cut drug prices by as much as 90%.

Blog post

“It’s a classic catch-22: between tariff pressures and price control promises, generics are being squeezed from both ends.”

How industry leaders are navigating the storm

Blog post

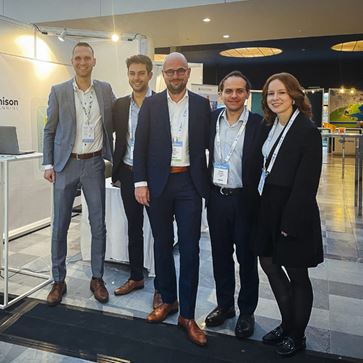

Some leading players have acted quickly to tackle this crisis. At the 2025 Gartner Supply Chain Symposium/Xpo™, Joseph Bitterman, VP of Supply Chain at Johnson & Johnson Innovative Medicine, shared how the company is leveraging a digital twin of its global supply chain.

"Our digital twin provides a virtual replica of the global supply chain, allowing us to simulate the impact of tariffs across markets and run scenario planning to evaluate sourcing alternatives in real time."

Others are investing billions in US-based manufacturing to avoid future tariff risks. But these are long-term moves, with timelines stretching five to ten years before the benefits are realized. In the meantime, agility and advanced planning will be critical to staying competitive.

Blog post

The silent risks of regulatory and research cuts

Blog post

Tariffs may dominate headlines, but they aren’t the only threat. Cuts to FDA staffing and NIH research funding could have far deeper, long-lasting consequences.

Reduced FDA resources could delay new drug approvals, slow approvals of new manufacturing capacity, and weaken oversight on industry compliance with GMP. Combined, these delays may stall innovation and put patient safety at risk.

Blog post

Meanwhile, cuts to NIH research grants threaten to choke off the early-stage discovery pipeline. While the effects may not be felt immediately, they could dramatically limit the availability of new therapies in the next decade. These changes could be even more damaging than tariffs over time.

The triple threat unpacked

Tariffs may have triggered this crisis, but they are only one piece of the puzzle. The biopharma industry is now facing a triple threat:

- Tariffs on medicines and raw materials

- Price pressures that conflict with rising costs

- Regulatory and research cuts that could slow innovation and safety

“Short-term tactics like scenario planning and network redesign are vital, but they won’t be enough. Safeguarding the long-term health of the industry will require smart investment, structural resilience, and the agility to adapt.”

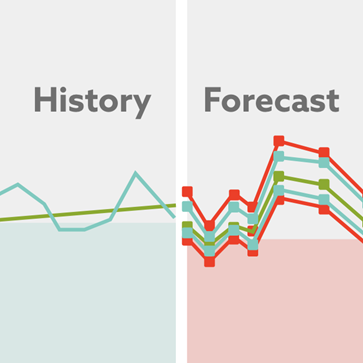

Navigating uncertainty through advanced supply chain planning

Turning disruption into opportunity requires more than quick fixes. Advanced planning strategies that combine scenario analysis, digital twins, and cross-functional collaboration can build a resilient supply chain that’s ready for sudden shocks.

Blog post

- Simulating ‘what-if’ scenarios to stay ahead: Scenario-based planning enables teams to model “what-if” situations such as sudden tariff increases or unexpected supplier shutdowns. For example, a global generics manufacturer could identify cost-saving sourcing alternatives before a new 25% tariff on imported APIs takes effect, allowing them to pivot without losing profitability.

- Using digital twins to optimize without risk: Digital twins create a virtual replica of the global supply network, helping companies spot bottlenecks and optimize sourcing decisions without disrupting day-to-day operations. For example, a biotech firm could use this technology to quickly shift production to alternate facilities when FDA inspection delays threaten a critical drug launch.

Blog post

- Connecting planning layers for smarter investments: When strategic, tactical, and operational planning are connected, companies gain clearer visibility into long-term risks and trade-offs. This insight supports smarter investments in manufacturing, sourcing, and R&D capacity.

- Breaking silos and accelerating decision-making: By uniting teams around a single, integrated planning ecosystem, organizations break down silos and accelerate decision-making when speed is essential.

Blog post

Bringing all these elements into one unified platform, OMP’s Unison Planning™ combines scenario modeling, digital twins, and cross-team collaboration. This proven platform tackles common industry challenges, empowering pharma leaders to make faster, smarter decisions that deliver real business results.

Blog post

Building resilience for 2025 and beyond

The takeaway? Disruption isn’t going away. But with the right tools and strategies, biopharma companies can move from reactive firefighting to proactive resilience. And resilience, in today’s volatile world, is the new competitive advantage.

Want to dive deeper into how leading pharma companies are navigating uncertainty? Read the key takeaways from Joe Bitterman’s presentation at the Gartner Supply Chain Symposium/Xpo™ and learn how J&J uses digital twins and scenario planning to stay ahead.

Allen Jacques

Business Development Manager Life Sciences

Biography

Allen is in life sciences business development at OMP. A veteran planning and operations leader, he has served as VP of Global Technical Operations & Biologics and External Manufacturing for Leo Pharma, VP of Network Supply Planning at Pfizer, VP of Pharma Supply Chain at Aera Technology, as well as holding director level roles at Baxter and Wyeth. He holds a BS in Microbiology from the University of Maryland and did graduate studies in Biochemistry at Johns Hopkins University.