Beyond what-if: boosting supply chain resilience through probabilistic planning

Broes De Cat and Jonathan Dalle - February 6, 2024

How can companies make their supply chain more resilient? One way could be to deploy a probabilistic supply chain planning model on top of current optimization models. We’ve developed a prototype for such an approach in our Unison Planning™ solution. Here’s why and how it works.

Supply chains need to be more resilient by design

Resilience has become a major focus in recent years as disruptions of different kinds are expected to occur more frequently. For instance, companies have experienced how climate-induced disruptions such as floods, wildfires and hurricanes can severely affect their global supply chains. At the same time, geopolitical tensions add uncertainty to raw material availability and prices, and can further reduce access to manufacturing or distribution facilities.

Supply chains should therefore be more resilient by design. But how?

What-if scenarios have their limitations

Blog post

At OMP, we look at it this way: the future is shaped by events as well as by decisions made along the way. This means that there are many future scenarios possible, some more probable than others. In addition, some scenarios are more favorable for the company than others.

But how can we predict these possible pathways? And how can we shape our supply chain and related decision-making in such a way that we avoid going down an unfavorable path?

Blog post

In a classic planning approach, planners are able to evaluate the impact of disruptions that might happen in the future through "what-if" simulations. For example, what would happen if a plant shuts down or what if a supplier has long-standing reliability issues? These types of what-if simulations have proven to be very valuable, but there are two important limitations.

Firstly, verifying all possible disruptions manually would mean running a huge number of scenarios, which is unmanageable, especially if you want to include scenarios where multiple events occur simultaneously. Secondly, the what-if approach treats every potential disruption equally, irrespective of how likely it is to occur. The approach does not factor in the probability of a particular disruption actually occurring.

Scrutinizing the digital twin for critical uncertainties

To address these limitations in a way fundamentally different from this deterministic approach, we believe that probabilistic planning is the key to managing uncertainty. Here’s how we do that in our prototype.

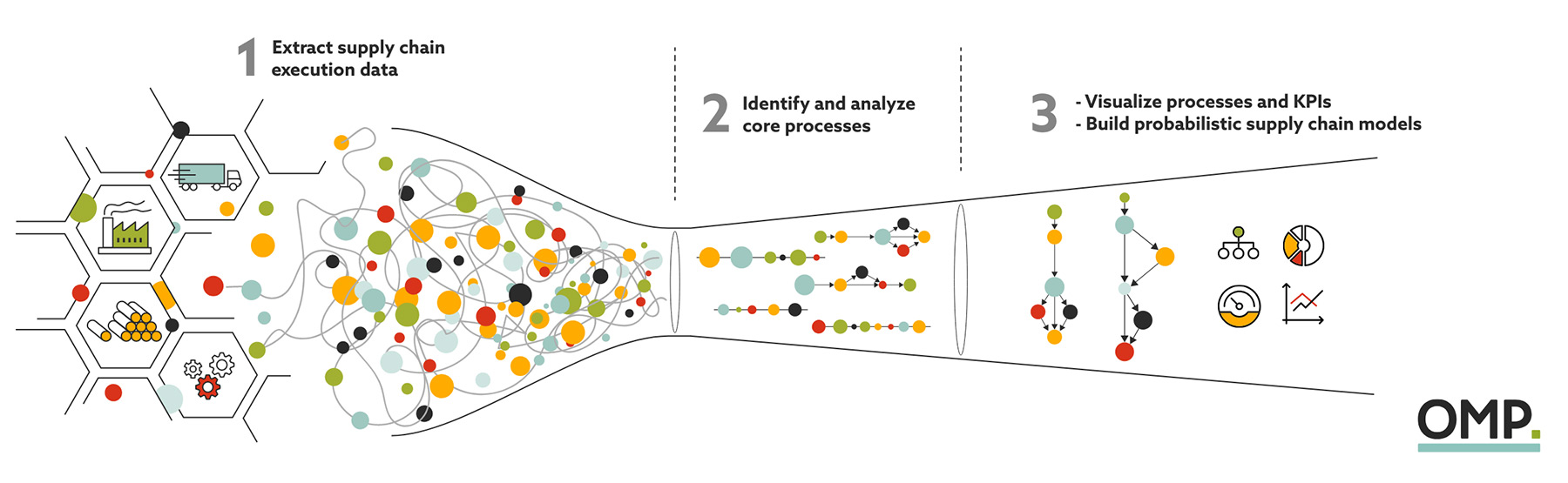

We first analyze the supply chain digital twin in detail to identify the parameters most susceptible to uncertainty, such as supplier reliability and transport lead times. Because fluctuations in these critical parameters could cause significant disruption across the supply chain, this analysis is crucial if we are to develop effective mitigation strategies.

Using advanced process mining techniques, we look at historical data such as sales records and execution data, along with forward-facing data such as macro-economic trends, and long-term business strategies and objectives, to analyze the impact of uncertainty.

Monte Carlo sampling overcomes the limitations of deterministic planning

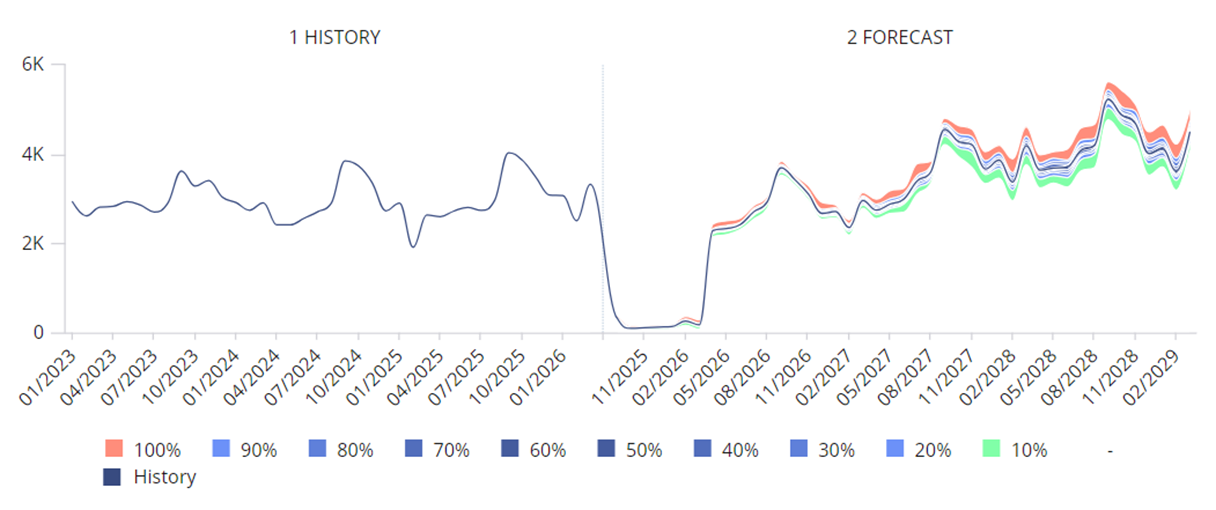

Monte Carlo sampling is then applied to the model, resulting in a huge set of scenarios. Each scenario consists of a combination of events based on the probability that they actually happen. Optimization is then used to generate a plan for each of those scenarios.

By analyzing the results, potential bottlenecks and pockets of improvement in the supply chain can be identified. For example, the analysis might reveal a 15% chance of a particular machine becoming a bottleneck and give a related risk score for the service levels of the products impacted by this event.

This Monte Carlo sampling overcomes the limitations of deterministic planning. It evaluates a huge number of events occurring simultaneously, without having to model hundreds of what-if scenarios manually while taking into account the probability of each event occurring.

Monte Carlo sampling methods are not just applied to supply chains. Interestingly, these methods are increasingly used to assess the risk of large construction projects running out of time or budget.

Blog post

Making optimization business strategies a continuous process

This analysis should be a continuous process if we want to make the supply chain less vulnerable to disruptions. We expect that probabilistic planning will eventually replace the deterministic approach as the prevailing supply chain planning paradigm.

What’s more, Unison Planning™ already provides the building blocks for this probabilistic approach, as we proved with our prototype. However, further research is needed, especially on how to bring the approach to real business cases. Join us on this exciting journey by submitting your business case.

Ready to uncover how probabilistic planning can make your supply chain more resilient?

Broes De Cat

Product Innovation Manager at OMP BE

Biography

Broes finds his challenge in shaping OMP’s product road map to support the supply chains of the future. He takes a broad approach to supply chain resilience, deploying techniques such as process mining, building models from execution data, and developing optimization and business rules for hyperautomation, as well as stochastics and ML.

Jonathan Dalle

Presales Architect at OMP USA

Biography

Being primarily involved in the early stages of projects, Jonathan enjoys collaborating closely with customers to shape a supply chain planning solution that meets their current needs and future aspirations.