3 strategies to outsmart US tariffs and win the supply chain power shift

Philip Vervloesem - July 23, 2025

Five months after US President Trump launched the first wave of tariffs, supply chain leaders around the world are still racing to understand the impact and respond effectively. While some strategies are broadly applicable, risks and priorities vary significantly across industries.

The imposed tariffs have sent shockwaves through the global economy, adding yet another layer of complexity to supply chains already under pressure. With little warning, new measures are introduced, adjusted, or withdrawn, making long-term planning feel like a game of Whack-a-Mole. Resolve one issue, and another quickly emerges. Retaliatory countermeasures and ongoing trade negotiations have only fueled the volatility, disrupting operations and global supply flows on a massive scale.

In this climate, companies are moving quickly to strengthen their planning capabilities and build more resilient networks. This article explores the most effective tactics Fortune 500 companies are using in response, highlighting where and how these strategies are taking shape across different industries.

3 supply chain strategies to mitigate the financial impact

Across industries, many companies are passing increased costs to customers. But more importantly, they’re using smart supply chain tactics to soften the financial blow. From what we see , supply chain leaders are adopting three main strategies, leveraging the capabilities of advanced supply chain planning solutions.

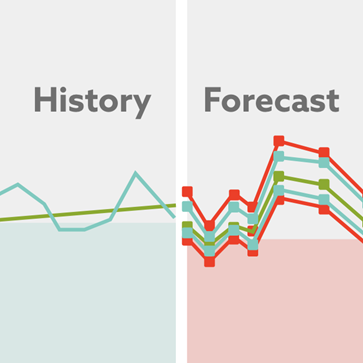

1. Running more frequent and advanced scenario planning

Blog post

Across all industries, companies are accelerating their use of scenario planning to keep up with the pace of change. Rather than waiting for monthly S&OP meetings to explore a handful of options, many are now running dozens of “what-if” simulations each week. In fact, the tariff conflict is accelerating the shift toward decision-centric planning.

At Evonik Oxeno, a leading chemical manufacturer, decision-centric planning plays a key role in managing ongoing disruption, including the impact of tariffs. “Before, we used to create maybe five to ten scenarios a month. Now, we can generate hundreds every week,” says David Kochanek, Supply Chain Solution Manager. Using Unison Planning™, the team rapidly models trade-offs in pricing, sourcing, and inventory to mitigate risk and protect margins. The stakes are high: even minor tariff shifts on raw materials can upend the profitability of entire product lines.

Blog post

“Before, we used to create maybe five to ten scenarios a month. With Unison Planning, we can run hundreds every week." - David Kochanek, Supply Chain Solution Manager at Evonik Oxeno

Blog post

A major generics manufacturer leveraged early simulations to identify cost-saving sourcing alternatives just ahead of a new 25% tariff on APIs. Meanwhile, high-end pharmaceutical producers are using scenario planning to proactively model from the impact of policy shifts and regional supply disruptions, while keeping service levels intact.

In the metals industry, where volatility is a constant, planners are relying on rapid simulations to assess alternative shipping routes, adapt sourcing strategies, and respond quickly to shifting tariff zones. Meanwhile, in the consumer goods sector, scenario planning is helping companies navigate pricing and procurement decisions, especially for slower-moving, high-margin products like cosmetics and premium healthcare items, where every point of margin matters.

Blog post

2. Strengthening and diversifying supplier networks

Blog post

Another key response to tariffs involves rethinking supplier networks. Leaders are focusing beyond cost on geographic diversity, contract flexibility, and risk reduction. They continuously evaluate supplier performance and tariff exposure, renegotiate contracts, onboard new suppliers, and adjust networks to strengthen resilience.

When tariffs began to affect Dow’s global sourcing of raw materials, the company responded not just by tweaking its logistics but by fundamentally rethinking its sourcing strategy. Using Unison Planning to optimize inventory and better coordinate across the extended network, Dow managed to reduce pressure on margins and shorten its planning cycles to keep pace with changing policy. Similarly, Nestlé took steps to balance cost efficiency with continuity of supply, adjusting both procurement and logistics strategies to enhance flexibility. For many in the consumer goods sector, this shift toward dual-sourcing and more regional partners marks a clear departure from traditional sourcing models that prioritized cost above all else.

Blog post

As part of this broader shift, some companies are also reassessing where production happens. While localization isn’t a one-size-fits-all solution, it can complement diversification by reducing dependency on global networks in key markets. L'Oréal, for instance, is reevaluating its sourcing balance between the U.S. and Australia/New Zealand to better align production with market needs.

Similarly, JDE Peet’s delayed a planned merger of its U.S. and EU/Asia operations to fully understand the tariff implications before proceeding. Advanced planning tools play a critical role in guiding these decisions, helping companies weigh trade-offs and build supply networks that are both efficient and resilient.

3. Harnessing real-time visibility into supply chain exposure

In a climate of rapid policy shifts, real-time visibility is crucial. Leaders need to understand where their exposure lies — from raw materials and inventory to transport routes and regulatory exposure. Advanced planning platforms offer the end-to-end visibility needed to track changes as they happen, enabling faster, more informed decisions.

At Johnson & Johnson Innovative Medicine, Vice President of Supply Chain Joseph Bitterman highlights the power of a digital twin: “Our digital twin gives us real-time visibility through a virtual replica of the global supply chain. Unison Planning helps planners evaluate trade-offs, simulate the impact of uncertainty, and make faster, smarter decisions as we scale APT 2.0.”

"Our digital twin gives us real-time visibility through a virtual replica of the global supply chain."

This level of visibility is proving critical in industries where tariff rates vary by region and product. With end-to-end insights into inventory, demand, pricing, and transport flows, companies can adjust production or reroute shipments with precision. Many are even building custom dashboards to continuously monitor exposure and trigger faster decisions.

What the tariffs are teaching supply chain leaders

In summary, while the imposed tariffs continue to send ripples through the global economy, they’re also driving smarter, faster, more strategic supply chain practices. Across industries, businesses are responding by upgrading planning capabilities, rethinking supplier networks, and investing in proactive scenario planning.

One clear takeaway? Flexibility is no longer optional. It’s now a core capability for any supply chain hoping to thrive in uncertainty.

Want to see how Unison Planning helps supply chain leaders navigate complexity and change? Explore the Evonik Oxeno case study to learn how they’re using scenario planning to stay ahead in a volatile global market.

Philip Vervloesem

Chief Commercial & Markets Officer at OMP

Biography

With 22 years’ supply chain digital transformation experience in a whole range of industries, Philip currently leads OMP’s business and market development globally while heading up the company’s US operations. Focusing on vision, strategy, and global community building, Philip has a proven history of boundary stretching and thought leadership in supply chain planning innovation, building new markets, and growing and supporting high-performing teams on both sides of the Atlantic.