From chaos to clarity: How end-to-end visibility can reshape your petrochemical supply chain

Robbert De Looff - October 20, 2025

There’s a moment I keep coming back to – one that perfectly captures the challenge so many leaders face right now. It happened during a recent strategy session with the supply chain manager of a global petrochemicals company. We were reviewing a flood of inputs: price curves, demand swings, disruptions from Red Sea traffic, even drought conditions in Panama. The kind of complexity that can quickly overwhelm decision-making. After laying it all out, the supply chain manager leaned back and said, “Between you and me, it feels like we’re flying blind. We just don’t know what’s coming next. And worse, we don’t know how to act on it.”

Blog post

If that sounds familiar, you're not alone. I’ve heard this same frustration in boardrooms and planning meetings across the industry over the past year. And it reflects a hard truth: your supply chain is likely more fragmented than you think. When raw material prices fluctuate wildly, labor shortages persist, regulatory demands tighten, and geopolitical shocks disrupt shipping routes, it’s not just one team solving one issue. It’s multiple teams, each tackling their own piece of the puzzle, often without talking to each other and without the visibility or tools to make confident decisions. This isn’t just exhausting; it damages profitability.

“What if you stopped chasing disruptions and started anticipating them?"

Blog post

That’s where value-driven supply chain planning comes in. More than a buzzword, it’s a deliberate approach to aligning production, logistics, and sales in a way that continually steers your business toward margin-maximizing outcomes. And it starts with something deceptively simple: visibility.

End-to-end planning is no longer a luxury, but the baseline

Blog post

Fragmented planning systems can’t keep up with today’s complexity. If you’re still managing production here, logistics there, and demand forecasts in a separate silo, your organization is losing valuable time and margin.

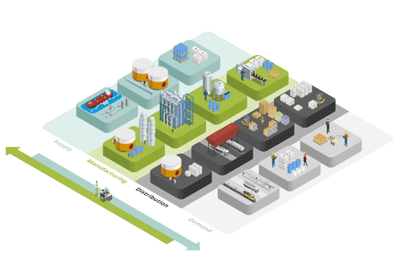

What you need is a unified, digital model of your entire supply chain— not just one plant or region, but your entire operational network. Cracking units, campaign plans, batch production flows, inventory positions, customer demand, and contract constraints are all considered in one platform. With this level of visibility, you don’t just react. You plan proactively, with confidence.

This means modeling trade-offs in real time. For example, increasing throughput in one facility, throttling back in another, or adjusting ethanolamines output by reallocating ethylene oxide fractions based on ammonia availability, as shown in our petrochemical supply chain e-book.

Blog post

But a digital model of your supply chain is only half the story. The real advantage comes from scenario planning, where you have the ability to test multiple “what-if” situations quickly. From there, you can compare the outcomes and implement the best option in the real world.

Why scenario planning changes the game

Blog post

Imagine this: one of your planners runs multiple overnight simulations — one for a polyethylene production cutback due to market oversaturation, another exploring the impact of a sudden shipping delay, and a third modeling carbon pricing fluctuations.

Before, these kinds of assessments could take weeks because they relied on manual data gathering, siloed spreadsheets, and lengthy cross-team discussions. Now, with integrated scenario planning, the same analysis can be completed overnight and reviewed the next morning.

Instead of walking into the office with a list of problems, your team arrives with clear, data-backed recommendations. This includes the margin impact of each option, the risk to customer commitments, and the sustainability trade-offs laid out. Decisions happen faster, with the confidence of seeing the full picture.

Blog post

The result is not just faster but better decision-making. For managers, it’s the difference between reacting to problems as they arise and proactively shaping informed, value-driven choices that strengthen the business.

Smart decisions begin with the right questions

- Should we commit capacity to a spot order with higher short-term margins, or protect volumes for a strategic long-term customer?

- Can we resequence next month’s production campaigns to reduce energy costs without missing priority deliveries?

- How will adjusting throughput to meet sustainability targets affect quarterly profit?

With scenario modeling built into the planning process, these become high-stakes business questions that can be answered with data rather than guesswork.

One global polymer producer we work with faced a complex challenge: frequent changeovers were eating into margins and straining service levels.

“Using scenario modeling to align market signals with plant-level constraints, they developed a campaign plan that reduced changeover time by 15 percent while strengthening both service and margins."

It was a fast, viable solution to a complex problem, turning operational gains into commercial advantage.

The future belongs to the agile

The petrochemical companies succeeding today embed visibility and cross-functional alignment deep into their supply chain culture. Instead of waiting to be surprised, they proactively build plans around what might happen. In this way, they turn that uncertainty into a competitive advantage. This isn’t just risk mitigation but value creation under pressure.

Blog post

Ready to see what that looks like?

Want to learn how top chemical producers are staying ahead of disruption?

Explore the practical strategies and real-world impact of scenario-driven planning in our latest e-book.

Robbert De Looff

Excellence Manager Chemicals at OMP BE

Biography

Robbert is dedicated to maximizing the value of OMP's chemical solution for customers, striving for optimal efficiency every step of the way. Driven by a passion for sustainability and a fascination with optimization and value realization, he's always on the lookout for groundbreaking industry solutions to tackles challenges head-on.