Navigating supply chain uncertainty: time to adopt new ways of planning

Jasper Wouters - March 21, 2023

Picture this: You're driving down a winding road when suddenly, a thick fog rolls in, obscuring your vision to just a few feet in front of you. As you carefully maneuver through the fog, you’re forced to rely on uncertain assumptions and make quick decisions. You must anticipate what might lie ahead and adjust your speed and direction accordingly.

Much like driving through foggy conditions, managing a supply chain can be challenging, as decisions often need to be made based on imperfect information and under varying levels of uncertainty. Decision-makers have to navigate through unpredictable market conditions, demand fluctuations, and unforeseen disruptions.

In my experience, this is one of the key challenges in supply chain planning. But luckily, recent advances in computing power and the development of novel analytics provide a potential path forward to better address this uncertainty.

In this blog post, we'll examine how these innovations are helping supply chain professionals improve the performance of their supply chains. So sit back, buckle up, and follow me through.

Sources of supply chain uncertainty

Today’s highly interconnected and complex supply chains are increasingly vulnerable to uncertainty, which can have multiple sources, including:

- Stochastic behavior — variability in lead times, product quality (perhaps scrap or obsolescence), and customer demand, for example, leading to unpredictable outcomes in procurement, manufacturing, and distribution.

- Imperfect knowledge of the supply chain — arising from inaccurately recorded inventory levels or lack of visibility and information sharing between entities in the supply chain, for example; or

- Unexpected events — completely beyond company control, such as a pandemic.

Blog post

Variability is a source of uncertainty mostly when it is not precisely predictable. To illustrate this with an example: an oscillating sine wave varies over time but, in the absence of noise, can be fully predicted with the right parameters and hence is characterized by variability but not uncertainty.

Blog post

While it might be possible to reduce some of this uncertainty, it will typically not be possible to fully eradicate it. Companies will therefore need to develop strategies to successfully operate in this environment, focusing on robustness (the ability to respond to unforeseen events) and resilience (the ability to recover from disruptions).

Supply chain planning as a multifaceted subject

Supply chain planning is multifaceted, often divided into three distinct areas:

- Strategic planning, focusing on supply chain design and, over the longer term, decisions to create, merge or close down operations, possibly with the help of partners;

- Demand planning, managing and predicting future demand, mostly with a medium-term horizon of months up to several years ahead; and

- Supply planning, determining inventory policies and making appropriate procurement, manufacturing, and distribution decisions.

Each of these areas imposes distinct requirements on the planning solution, leading to different analytics being deployed.

Better strategic planning with network analytics

Blog post

Established strategic planning solutions — which often rely on mathematical programming, discrete event simulation, and risk management — are increasingly supplemented by network analytics tools. These tools use graph theory to assess whether a supply configuration is robust and resilient, deploying known algorithms for problems such as routing, flow, and clustering.

Blog post

Machine learning making advances in demand and supply planning

Blog post

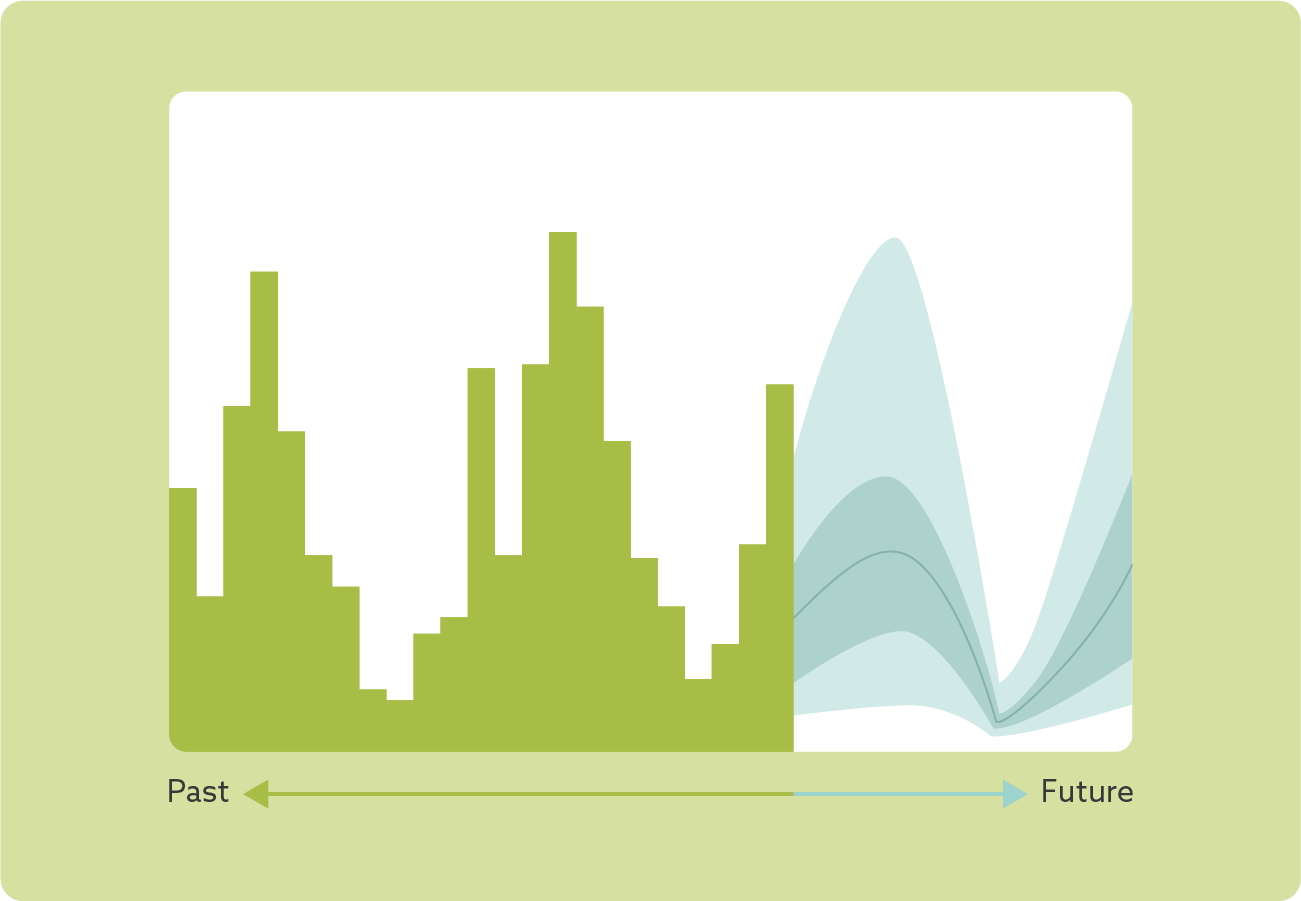

In recent years, machine learning has established itself as a game-changer in quantitative forecasting in demand planning. This revolution also introduced probabilistic models, offering a better understanding and quantification of the uncertainty of future demand predictions.

Similar probabilistic models can be used in supply planning, with supply parameters and constraints (such as lead times) treated as distributions rather than discrete point estimates.

The key challenge of the probabilistic approach, however, is the explosion of the computational search space for decision optimization making it essential to develop and deploy smart reduction or sampling techniques to use data efficiently. Reinforcement learning — the third machine learning paradigm alongside supervised and unsupervised learning — could play a role here too, by providing better and smarter approximate or heuristic techniques for decision-making in this context.

Blog post

Gaining experience through selected pilots

It’s clear that machine learning and big data analytics have enormous potential to improve supply chain planning, and hence supply chain performance. Multiple novel techniques are becoming available and can be used to complement existing techniques in pursuit of better decision-making. With this evolutionary change, supply chain management will become even more data and analytics driven.

With so many great opportunities ahead, I recommend supply chain organizations explore these areas and invest in carefully selected pilot projects to gain experience and drive value. Managing a supply chain can feel like driving through thick fog, but with advanced analytics, we can navigate through the uncertainty and steer towards success.

Want to find out more about managing uncertainty in your supply chain?

Jasper Wouters

Associate Director at OMP BE

Biography

With a business management and analytics background, and more than a decade of experience in the industry, Jasper works with customers across the globe. He optimizes supply chains by implementing best-in-class planning processes, backed up by cutting-edge technology.