What do we really expect from a supply chain control tower?

Jan Snoeckx - October 18, 2021

Even though there’s still no consensus on the definition and scope of supply chain control towers, the concept continues to arouse interest among business executives, who rightly believe that a control tower should allow them to take full control of the entire supply chain. This is in stark contrast to the somewhat disappointing results from most current deployments out there. I’d like to make a suggestion about what the standard should be.

Everyone wants it, but…

Blog post

What’s the problem? In a Supply Chain Dive opinion article published in 2020, Gartner’s Christian Titze offered his critique on the subject, saying that “control towers are like the artificial intelligence of supply chain: everyone wants to have it, but nobody quite knows how it works.”

This seems to be the perfect breeding ground for a confused market with many half-baked solutions going live, offering little more than a data warehouse with BI reporting. In the best-case scenarios, these reports signal critical deviations occurring in the supply chain, pinpointing the causes. In the worst cases, they signal either too much or nothing at all. What most of them fail to do is provide actionable information.

Blog post

We all know how complex supply chains are, with all their interwoven levels of decision making. It’s one thing to discover that there’s a fire going on somewhere, it’s a completely different thing to know what you can do to fight it without causing too many undesirable side effects. I believe we should therefore establish a standard for supply chain control towers.

Four essential functionalities

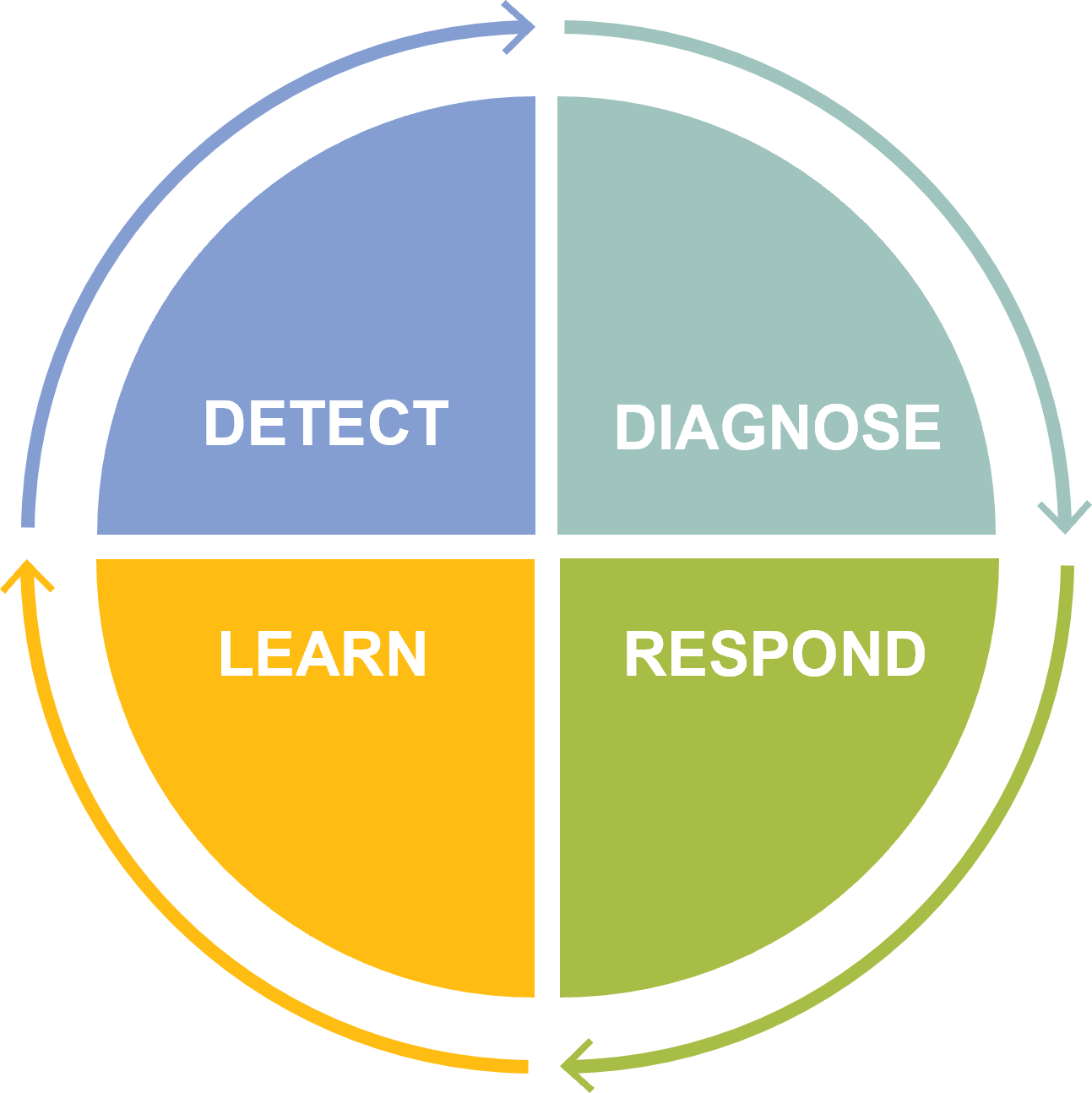

A control tower should offer four essential functional stages:

Blog post

- Stage 1: Detect - Any supply or demand event with a significant positive or negative business impact is presented clearly and at the speed of the business (meaning not always in real time but as close to real time as the business requires). The reporting should cover every level of the supply chain, from strategic to operational and from sourcing to delivery. It should also be configurable to allow companies to finetune the solution so that only the critical issues are signaled.

- Stage 2: Diagnose - The potential bottom-line impact of any signaled event (for instance on revenue, service level, or costs) can be calculated and presented, along with the probability of occurrence and its reach within the supply chain.

- Stage 3: Respond - Scenarios can be defined and benchmarked against each other, allowing the most viable option, in terms of current and future business impact, to be selected. The solution should also make it possible to integrate automated response scenarios and the conditions under which they will be triggered.

- Stage 4: Learn - A continuous improvement loop means that lessons are learned from the events to be integrated into the solution, gradually enriching the decision-making process with automated and semi-automated solutions.

Blog post

Giving business leaders what they beg for

In the past decade, multiple low-maturity initiatives have paved the way for a sea change in control tower approaches. We should first recognize the need for a telescopic digital twin as a solid foundation. The message has already reached hyperscale providers like Google and Amazon who are starting to develop a supply chain offering with the promise of real-time supply chain visibility. This would bring good progress at stages 1 and 2 (Detect and Diagnose), but control tower users should additionally be given access to smart planning functionalities. They could then develop viable scenarios and automated responses (stage 3) in their pursuit of continuous improvement (stage 4).

Because that’s what business leaders really mean when they’re begging for full control over their entire supply chain.

Do you dream of orchestrating your entire supply chain from one single platform? Discover what Unison Planning™ can do for you.

Jan Snoeckx

Former Innovation Lead

Biography

Fully immersed in supply chain for more than 20 years, Jan has wide-ranging expertise and the leadership smarts to inspire talented and effective teams. Currently heading up product development and marketing teams at OMP, Jan has a personal ambition to challenge supply chain status quo and bring innovation, technology, and people together for critical industries like consumer goods, life sciences, metals, packaging, and chemicals.