- industries

- chemicals

- business leader

BUSINESS LEADERS IN CHEMICALS

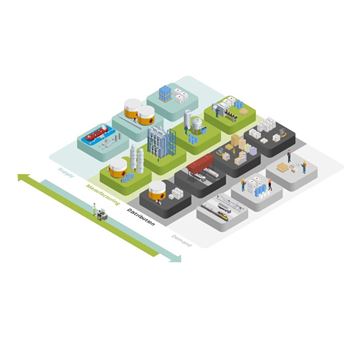

Production chains and value streams in the chemical industry are truly unique. As well as being inherently complex and subject to such variable demand, they involve a vast range of interconnected elements. These include everything from raw materials, base and intermediate products, to finished goods, co-products, and by-products.

The combination of many ingredients and operations brings with it huge planning and optimization challenges for decision-makers at both divisional and corporate level.

Just how do you keep all your business units and teams aligned? How can you extend collaboration beyond the business and become more agile in the face of disruptive change? And how can smarter planning make your business more sustainable? OMP for Chemicals helps you do this and more.

Integrating collaboration as a

key to success

Heavily intertwined value streams, when combined with complex chemical processes, make collaboration within and beyond business units a challenge, especially when companies constantly take turns as competitors, suppliers, and customers.

Unison Planning™ empowers overarching alignment within and beyond company fences, to produce optimal and feasible plans based on real-time information. The solution supports both centralized and decentralized planning approaches, depending on your corporate strategy.

Collaborate effectivelyInstant insights,

smart scenarios, and

raised responsiveness

In today’s market, high volatility is the new reality. Unison Planning™ offers end-to-end visibility across the entire value chain. OMP for Chemicals gives immediate insight into the causes and effects of disruptive change on your supply chain.

The solution uses embedded AI, ML, and solvers to generate alternate strategies and sharp evaluations that prompt you to anticipate issues rapidly and react in good time.

Deciding smarterPlanning for sustainability

Sustainability is high on everyone’s agenda. Leading chemical companies are discovering the advantages of smart planning in their sustainability efforts. The flexibility of Unison Planning™ means that all kinds of chemical and mechanical recycling can be part of the planning equation. Circular economy principles can be put into practice and, for sustainability, it supports both reporting and licensing processes.

Get greenerRelated content

OMP solution supports Corbion’s gradual transition to SAP S/4HANA

Leading food and biochemicals company Corbion has taken into operation a multi-ERP interface with their OMP planning solution to support the gradual transition to SAP S/4HANA.

Read the news

3 good reasons to standardize your supply chain

I have strong opinions about a debate that will probably never be settled (and it’s not about whether Ross and Rachel were on a break). It’s about whether companies should get their advanced supply chain planning solution customized to meet their specialized needs or instead adopt a standard template.

Read the blogEvonik plans complex chemical processes with OMP

Specialty chemicals leader Evonik rolled out a full-scope OMP planning solution to provide end-to-end visibility in their Performance Intermediates supply chain. OMP is now Evonik’s supply chain system of record and is seamlessly connected to their SAP ERP system.

Read the newsThe future of supply chain collaboration and ecosystems

The webinar discusses how companies now collaborate to a greater extent to make their supply chains more agile and resilient.

Watch the webinar

How planning systems can help customers plan sustainably

More and more companies are investing in sustainability, and there’s a good reason for that: climate change is one of the biggest issues facing humanity and we’re already seeing the consequences, with increasingly severe floods, shrinking ice caps, record temperatures and deadly droughts.

Read the blogWhat our customers say

“What OMP brought is the discipline that our organization needs. No-nonsense, straight to the point, I thought, okay, that’s what I want.”

Jack Eggels, General Manager Chemicals Operations at Shell

“OMP is the perfect solution to solve our complex requirements in a very dynamic, demand-driven business.”

Stefan Hauenschild, Sales & Operations Planning Responsible at Siegwerk Druckfarben

“OMP is capable of generating a value-based plan, including the complexities of our chemical network.

We now discuss value instead of volume!”

Rainer Fretzen, Head of Performance Intermediates at Evonik

“The OMP solution allowed us to integrate our planning and scheduling needs with our corporate SAP platform. OMP has proven the flexibility to support scheduling needs ranging from batch to continuous processes.”

Jim Carey, Supply Chain Manager at Eastman

Holistic collaboration

Integrated planning generates higher added value. But aligning a strongly intertwined network of value chains and installations — involving business units spread across the world — is not an easy task. Especially when you also have to consider make-or-buy decisions and swap deals.

How can you orchestrate all these stakeholders in pursuit of optimal value? How can you be sure your plans are feasible? And where do you find a planning tool that allows you to implement both centralization and decentralization strategies?

Planning with respect for manufacturing complexity

OMP for Chemicals, powered by Unison Planning™, builds a telescopic digital twin of the entire value chain, respecting all its complexity, including simultaneous planning of batch and continuous processing, campaign planning, variable bills of materials, and throttling. Its advanced modeling power allows your planners to replicate the actual reality of what’s really going on inside your installations, reactors, and tanks. The ‘one model, one plan’ logic means that business leaders can apply integrated planning cycles across every product line, business unit, and team, and across every planning function and horizon. This establishes fluid, multi-directional orchestration between network design, demand planning, S&OP, and scheduling.Collaboration within and beyond the company walls

Through its comprehensive modeling and its open platform architecture, OMP for Chemicals is designed to support, align, and harmonize collaboration across multiple departments and stakeholders while balancing conflicting interests and agendas.It then takes collaboration a step further. In the chemical industry, companies constantly switch positions, taking turns as competitors, suppliers, or customers to each other. OMP for Chemicals seamlessly handles all this complexity. As a truly inclusive planning solution, it manages the entire production process and every stakeholder.

While optimizing your value streams, the solution also integrates co- and by-product planning; it optimizes your own production and capacities and those of your CMOs, and recommends the smartest make-or-buy and swap decisions. It even allows your demand planning, forecasting, and operational planning to use different forecast probabilities to meet the distinct needs of long-term contracts and spot opportunities. On top of that, it makes it easy to maintain sales and purchase price formulas, including using markers and price indices.

Optimal value, feasible plans

Embedded AI, ML, data science, and solvers empower decision-makers to optimize value from end to end while taking into account typical complexities such as demand priorities, materials bottlenecks, reducing changeover and material costs, and optimizing hydrocarbon use.But that’s not all. The technology doesn’t just help in planning for optimal value. It also guarantees that your plans are actually feasible. Performant data management and integration features — including a live connection to SAP or a similar ERP system — can feed real-time information from your installation, reactors, and tanks to the planning solution. You can be sure that everything you plan is aligned with reality and can actually be carried out successfully.

Central and decentral planning

Whether you’re keen on centralizing or decentralizing your supply chain often depends on a combination of the nature of your product portfolio, the physical and geographical layout of your global supply chain network, and your corporate strategy. Both options have their merits.

In some cases, you may feel it’s wiser to concentrate decision power at the business unit level. Solving challenges the integrated way — over multiple business units at the same time — often unlocks greater efficiency and better margins for many companies focused on base and intermediate chemicals.

OMP for Chemicals is valued highly by leading global manufacturers for its full scope and superior performance in managing integrated value chains. Achieving this across multiple business units at the same time, while balancing installation capacities and production flows internally and externally — either towards customers, or through competitor swaps — is the thing that most appeals to users. But then, identifying the most advantageous transport and logistics options, that’s the deciding factor.

With its comprehensive model, flexible architecture, high-performance calculation engines, and capacity to handle massive quantities of data effectively, OMP for Chemicals sets the stage for overall optimization on a global scale across multiple business units while still supporting decentralized decision-making.

This gives business leaders the flexibility to position themselves at either end of the centralization spectrum or quickly shift if the pendulum swings the other way.

Growing more responsive in a disruptive market

In today’s reality, highly volatile commodity prices and sudden shifts in demand are no longer exceptions to the rule. They’ve become the rule. With margins squeezed to the extreme, chemical companies demand supply chain planning solutions that grant instant insight into the causes and effects of disruptive change, generate smart scenarios fast, and raise responsiveness.

End-to-end visibility over supply and demand

Whatever markets they cater for, chemicals manufacturers are more brutally exposed to change than ever. Commodity producers struggle to respond to supply and price disruptions in raw materials, oil, and gas. Downstream producers face erratic demand patterns. And midstream producers find themselves trapped on both sides at the same time.

OMP for Chemicals builds on Unison Planning™ to achieve end-to-end visibility and control over the entire value chain. The fully integrated production and distribution planning is powered by robust engines, advanced intelligence, and a live ERP connection. 360° analytics with intuitive dashboards and personalized overviews keep you in the loop with critical alerts, while embedded AI, ML, and solvers immediately generate alternative strategies and offer insightful evaluations to help you make smart decisions fast. Data science brings its own extra value, with OMP‘s Data Genie using past data, such as historic machine rates, to optimize solver models.

Decision-makers in finished goods and specialty products particularly appreciate OMP for Chemicals for its demand sensing features incorporating point-of-sale data to improve forecasting, and its high-end reporting tools that help maintain an overview of large numbers of SKUs.

With all this in place, it’s a simple task to react swiftly and effectively when confronted with sudden hiccups in demand or supply, or unexpected price evolutions, reactor downtimes, and production incidents.

Extra features for extra speed

OMP for Chemicals is packed with special features that empower business leaders to respond faster to inherent changes in demand and supply.

On the demand side, planners can simulate due-date and quantity changes, and map their impact on the plan, with reporting tools visualizing any gaps. On the supply side, the planning solution offers ample functionality to make the model stick even closer to the production process’s inherent variability.

In addition to its ability to simultaneously plan continuous and batch processes and to take into account variable bills of materials, OMP for Chemicals allows planners to treat the throughput factor as a planning decision (throttling). It considers the physical reality of reactor behavior due to, for example, changes in outside temperature or the effect of catalyst quality downgrading over time. The option to maintain nominal (real) capacity as either a percentage of the technical capacity, as stored in your ERP system, or via an absolute volume per unit or a unit over time, makes it possible to plan for variable reactor capacity.

Ultimately, OMP for Chemicals checks whether production is running ahead or behind on a plan or campaign. It then triggers appropriate user actions, such as adapting throughput when you’re running behind, or exception-based alerts that prompt you to anticipate and react in good time, based on smart scenario alternatives and insightful evaluation.

Planning for sustainability

As companies have been growing more aware of the impact of their operations on environment, economics and society as a whole, sustainability issues have moved up on corporate agendas. Although new corporate investments, technological innovations and changes in the physical layout of plants, installations and logistics all have a major impact on energy-efficiency and carbon neutrality, leading chemical manufacturing companies are progressively turning to smarter planning tools for additional support. Indeed, where investment decisions only start affecting the baseline in the long run, smarter planning reduces carbon footprint, emissions, energy consumption, raw materials supply and waste on much shorter notice.

As companies become more aware of the impact of their operations on the environment, the economy, and society as a whole, sustainability issues have moved up corporate agendas. New corporate investments, technological innovations, and changes to the physical layout of plants and installations, and evolving logistics all have a major impact on energy efficiency and carbon neutrality in the long run. Leading chemical manufacturers are now progressively turning to smarter planning tools to help them reduce carbon footprint and emissions, and urgently review energy consumption, the use of raw materials, and waste management.

Smarter planning, smaller footprint

OMP for Chemicals helps customers minimize carbon footprint and optimize the comprehensive spectrum of energy consumption in support of carbon neutrality. The planning solution treats all forms of energy and emissions as key complementary parameters in planning and optimizing sourcing, production, and logistics.

Better still, the system feeds corporate and licensed carbon, energy, and emission registration tools with accurate data, from the long-term planning stage to actual production, enhancing environmental reporting quality and supporting your permit and licensing policies and commitments.

Planning as a stepping stone towards circular economy

As more and more companies embrace the concept of recycling, effective planning solutions need to extend their functionality to include the circular economy. With its flexible model, OMP for Chemicals is well placed to integrate all types of chemical and mechanical recycling into the planning equation. Helped by AI, ML, powerful embedded solvers, and data science features, planning and optimizing for the circular economy becomes a simple task.