Solution for your complex supply chain in life sciences

Business leaders in the life sciences industry deal every day with one of the most complex supply chains imaginable. Theirs is a world of high-tech production processes, scattered over a hybrid, strongly intertwined network of internal and external production, and packaging and distribution nodes.

Commitment to patients is the prime concern, of course, while compliance with health regulations brings additional challenges. So how do you gain end-to-end visibility over your entire supply chain ecosystem? And how can you retain high product availability while keeping inventory and capacity buffers low? Here’s how OMP for Life Sciences helps companies navigate and overcome these challenges.

End-to-end visibility

Global life sciences supply chains are very complex. Business leaders need to align interconnected production sites worldwide, and balance in-house production and contract manufacturing, while dealing with dual sourcing strategies from production to distribution.

OMP for Life Sciences builds a digital twin of your entire extended supply chain ecosystem. Its ‘one model, one plan’ logic provides an integrated platform for all stakeholders, offering full end-to-end visibility over the entire supply chain, including suppliers, CMOs, third-party logistics, and other partners, while seamlessly integrating all planning horizons, functions, and roles.

With its integrated logic, OMP for Life Sciences eliminates disconnects between planning horizons, allowing optimization at global level, and avoiding the risks inherent in making decisions with only partial supply chain visibility.

Top service levels at lower inventory and capacity buffers

OMP for Life Sciences reconciles top service levels with profit optimization. It smartly adjusts production, packaging and distribution lines, capacities and networks, while optimizing inventory levels of intermediate and finished products, and synchronizing manufacturing equipment and packaging lines.

Capacity constraint solvers, self-learning data, data management, and integration features, all combine for a perfect sync between plan and reality. Attribute-based planning and pegging functionality allow you to plan for specific batch characteristics and shelf-life requirements, instead of planning on materials alone, letting you peg any demand and supply element according to rules integrated within the model, including regulatory constraints, quantity tolerance, and shelf-life.

Better compliance through collaborative planning

OMP for Life Sciences allows all the departments involved in clinical and commercial production, regulatory approvals, and quality control to work together in unison. By handling regulatory issues as an additional planning constraint, the planning solution considers which in-house or CMO facilities are authorized to produce a particular drug substance or product for specific customer segments and regions, and in what specified time frame.

Throughput times for quality controls can be added to the planning, allowing priority-based batch planning to meet critical deadlines or serve key customers. You can, for example, more easily anticipate patent approval, plan your commercial production and distribution networks in advance, and orchestrate both clinical and commercial capacity planning — even with shared equipment, product lines, or reactors.

Related content

What our customers say

“OMP helps us to get all our planners to work together globally, around the same process, using the same system, in the same way.”

Stef Vermeiren, Vice President Global Planning – Janssen Pharmaceutica at Johnson & Johnson

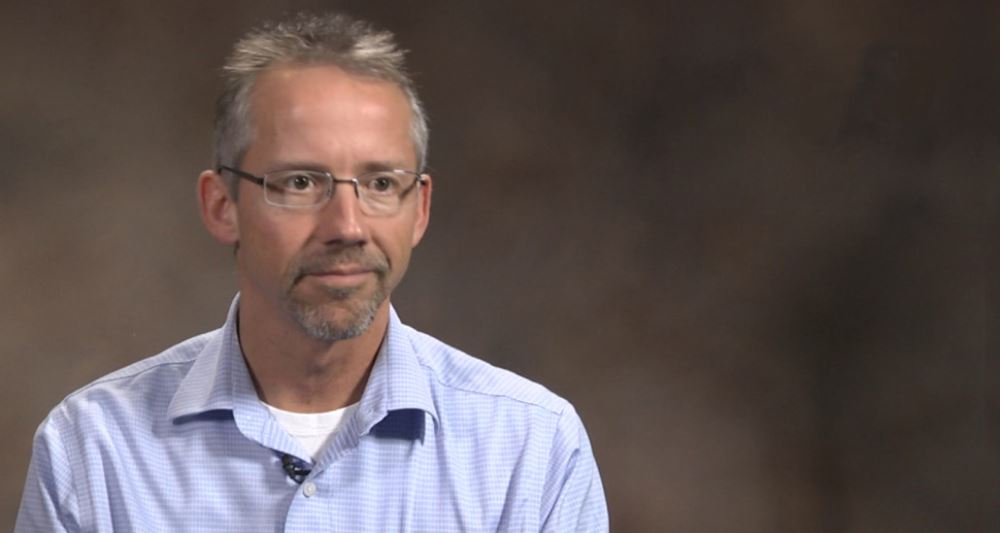

“They delivered us a solution that we're very happy with. That delivered exactly what we needed.”

Dean Bergman, IT Director at Avanos Medical

“An optimal supply chain is critical to making sure people, living with severe diseases, obtain their medicines on time. OMP offered the quality and robustness in the planning process we were aiming for. Manual activities from multiple sources are now automated within our new planning system of record. One common integrated process is now applied. This gives better control, greater visibility and a higher level of maturity, resulting in agile supply chains."

Nathalie Loicq, Vice President Global Supply Chain at UCB

“We were looking for an integrated, automated and scalable solution and that’s what we got from OMP.”

David Aherne, Senior Director Global Supply Chain at Alexion Pharmaceuticals

“Building our end-to-end planning capabilities on OMP allows us to integrate planning — horizontally, across supply chain, commercial, manufacturing and finance departments, and vertically from the reactive to the strategic horizon. With this, we can take advantage of digital modeling and scenario planning capabilities, and respond quickly to changing business environments, such as we have seen during the pandemic this year.”

Steffen Heinecke, Project Lead for Global Supply Chain at Roche