Are you ready for bumpy planning times ahead?

Léo Ducrot - September 17, 2020

“We plan, God laughs,” is an old Yiddish saying that most supply chain planners would find mildly funny these days. Uncertainty is part of every supply chain, yet the COVID-19 outbreak brings that uncertainty in both demand and supply to spectacular levels. What is the current situation and how is it going to unfold? Traditional forecasting techniques will be less accurate than they used to be. What can be done about that?

What is going on?

The situation resulting from the COVID-19 crisis impacts supply chains from both ends: the demand side and the supply side. Demand for goods and services has been hit in almost all sectors, with some even showing a total collapse because of lockdown measures. In some sectors, demand patterns have changed completely. The food industry has seen demand from restaurants and catering services vanish while demand from retailers has exploded. The supply side has also been impacted by uncertainty. Factory shutdowns and international trade restrictions have made the supply of raw materials and components unstable.

Blog post

Previous crises, such as the 2011 Tsunami in Japan and the floods in Thailand the same year, disrupted supply and demand in limited geographical areas but with a significant worldwide impact on supply chains because of globalization. Today, the primary disruptions are happening everywhere. Supply chain dynamics are extremely complex and difficult to predict due to the global nature of demand and fulfillment, the importance of international trade, and long lead times.

Blog post

What comes next?

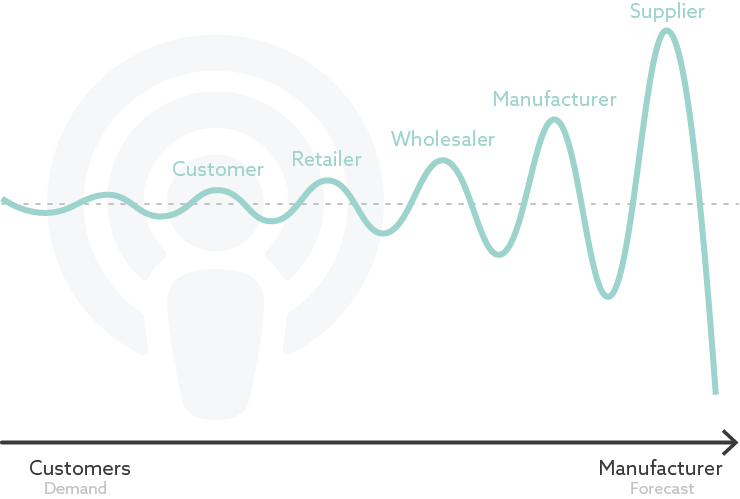

While some analysts have said that demand will go back to normal shortly after lockdowns end, I believe that forecasts will still be much less accurate for up to two years. Consumer demand has been highly unpredictable during the lockdowns due to instances of irrational panic buying as well as unprecedented demand patterns arising from changing consumption habits, different routines, and new hobbies. A lot of canceled purchases could result in a wave of buying later. These sudden changes in demand will most likely create a bullwhip effect, which will be more powerful than ever in the ongoing supply chain disruption.

Primary disruptions are happening at different times in different places in the world, and all these places have different lead times. It is almost impossible to predict the availability of products made from multiple components from multiple suppliers in different regions of the world. This situation will continue for a while, because economy restarts will most likely result in fresh breakouts from time to time in different places, as Prof. Yossi Sheffi explains.

Blog post

In current conditions, where supply chain footprints often spread across the globe, these sudden and frequent disruptions will hurt the supply stream in barely predictable ways. This could further fuel the bullwhip effect by disturbing the demand signal along the different supply chains. Anyone who ever played the beer game will remember that the slightest change in demand can cause much instability. The oscillations actually result from the reactions to the lack of material.

The bullwhip effect is not a pure demand phenomenon. A change in demand is amplified along the supply chain up to a point where it empties the supply chain. The sudden supply shortage then reinforces demand instability. Everything is interconnected, as Peter Senge pointed out so eloquently in his 1990 book The Fifth Discipline. Since COVID-19 launches a bullwhip effect by affecting both demand and supply, it is very unlikely that demand will return to normal any time soon.

Blog post

We can reasonably assume that forecast accuracy will remain lower than before the outbreak for quite some time. Demand planners will have a hard time for at least a year because the data gathered during these troubled times will be of little help in predicting future demand.

What should we do?

This is not to say that we’re completely at a loss. Demand and supply planners are now adjusting forecasts manually. At this point, forecasts are hardly more than educated guesses. We need to acknowledge this, accept the low accuracy, and look for planning tools that can be effective under these circumstances.

Blog post

Collaborative forecasting, with multiple parties — including customers — providing their insights to assess future demand and supply, is a smart move today, though not a cure-all. Analysis will be easier if portfolios are rationalized. It’s much easier to include external data if the number of products is kept as low as possible, avoiding the most severe bullwhip effects. But collaborative forecasting is resource intensive, and most customers are only willing to make this commitment to their more strategic suppliers. Unfortunately, supply chains are not always symmetrical and it is not uncommon for a company to be only a marginal supplier for its main customers.

Blog post

You can also deploy demand sensing to compensate for this loss in forecast accuracy, improving short term forecasting using point-of-sale data and machine learning models to identify underlying patterns. However, this demand sensing magic has its limitations in times of rapidly changing demand. It is best to engage data scientists who can continuously retrain the models and include additional external data where appropriate.

More responsive and less sensitive to forecast accuracy

Supply chains face disruption at both ends. Demand has become highly uncertain and the availability of supply is equally hard to predict. The combination causes a bullwhip effect expected to affect supply chains for several months. And, since most forecasting techniques use sales history, forecast accuracy will remain low next year too. In any case, the supply planning process will have to be much more responsive and less sensitive to forecast accuracy.

Do you need help mastering your supply chain?

Léo Ducrot

Advisory Manager

Biography

With his acknowledged expertise in supply chain planning and inventory optimization, Léo assists companies worldwide to improve their planning processes, aligning them more successfully with their corporate strategies.