How your supply chain business case will put you on track (and save you)

Steven Depue - September 8, 2020

Although the sporting rifle shooter Matthew Emmons (born 1981) was a medal winner at three successive Summer Olympics, the American will be forever remembered for his failure to strike a historic double in Athens in 2004. Firing his last and decisive shot in the final round of the 50-meter three positions, he mistakenly aimed for the target in the lane next to his. He shot right at the target’s center, but he was given a zero score. Great shot, wrong target!

You’ll always miss if your target isn’t clear

We must say we wouldn’t have pitied Mr. Emmons if we had been there. After all, what’s so difficult about aiming at the right target in rifle shooting? Just stay calm and keep a cool head.

But in business, it’s often much more difficult to identify your target. For example, what’s your goal in launching a digital supply chain transformation project? A return on investment within three years? That seems fair but doesn’t sound very ambitious and is way too vague to get you going.

Remember that you’ll always miss if your target isn’t clear. So, you’ll need to be much more precise when defining your targets, which is the first step in crafting a solid business case and vital to any project, not least a digital supply chain transformation project.

Aiming for the strategy-oriented approach

Defining targets in a supply chain planning project is easier said than done. We’ve seen quite a lot of supply chain leaders pitching their planning project with the promise of an x% increase in planning efficiency and a y% reduction in operational costs and stock levels. While using these metrics seems like the most straightforward approach from a supply chain perspective, it is insufficient from a company-wide perspective if the scheme is at odds with corporate strategy. You first need to outline the company’s strategic goals and then select the metrics that best fit this strategy.

Defining targets in a supply chain planning project is easier said than done. We’ve seen quite a lot of supply chain leaders pitching their planning project with the promise of an x% increase in planning efficiency and a y% reduction in operational costs and stock levels. While using these metrics seems like the most straightforward approach from a supply chain perspective, it is insufficient from a company-wide perspective if the scheme is at odds with corporate strategy. You first need to outline the company’s strategic goals and then select the metrics that best fit this strategy.

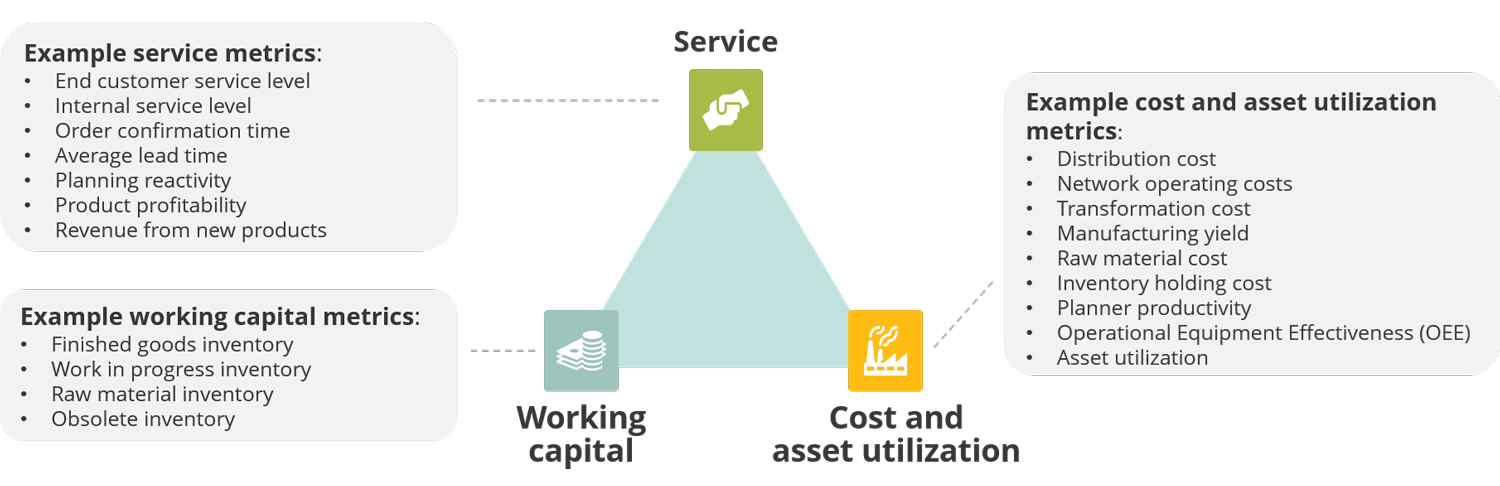

Cost-oriented metrics may be part of the solution, but you may also need to include service-oriented metrics such as demand responsiveness, product profitability, and revenue from new products, or operations-oriented metrics such as overall equipment effectiveness and asset utilization. The optimal combination of metrics differs from business to business, depending on industry-specific mechanics and on the strategy being pursued. It’s a matter of finding its place in the service-capital-operations triangle. We’ll elaborate on this topic in another blog post soon.

Where do you want to be in the triangle? You can optimize one corner (like Service), while minimizing another (Working capital), but then you’ll need the third one (Cost & asset utilization) as your flexible buffer [Example of a supply chain strategy assessment by OMP].

Don’t forget potential qualitative gains

While it is essential to improve KPIs, potential qualitative improvements should not be overlooked. A supply chain planning project can be a major vector in improving cross-functional, cross-departmental and global collaboration within a company. With better end-to-end visibility, people across the organization and in different departments learn to understand each other’s business challenges and preoccupations. This helps to reduce frustration and increase job satisfaction, essential elements in company performance.

A systematic approach

You don’t develop a business case on the back of a beer mat. Take your time and approach it systematically; interview key people in your organization to identify pain points and opportunities for improvement. Pain points might include, for example, the absence of operational policies with regard to work-in-process, the inability to run scenarios in S&OP planning, frequent use of expedited shipments, low demand accuracy, limited insight into upstream or downstream constraints such as storage space limitations, long lead times due to stringent MTO policies or inappropriate campaign planning.

You don’t develop a business case on the back of a beer mat. Take your time and approach it systematically; interview key people in your organization to identify pain points and opportunities for improvement. Pain points might include, for example, the absence of operational policies with regard to work-in-process, the inability to run scenarios in S&OP planning, frequent use of expedited shipments, low demand accuracy, limited insight into upstream or downstream constraints such as storage space limitations, long lead times due to stringent MTO policies or inappropriate campaign planning.

Make a list of the pain points and rate them against your targets. This allows you to prioritize the actions you want to include in your supply chain planning project. Then qualify and quantify the related costs and the expected gains, both one-time shots and recurring benefits. It will soon be clear which actions are a must-do and which are just nice to have. That, right there, is your business case.

Saved by the business case

Some people say that business cases are often already out of date by the time they’re written. While that may be true, one can never overestimate the importance of a well-designed business case. We were recently involved in a digital transformation project for a European equipment manufacturer when top management suddenly decided to tear off some of the local distribution centers. This strategic decision hugely impacted the supply chain organization and could have completely derailed the ongoing transformation project. Fortunately, the detailed business case allowed supply chain management to carefully adjust the project by focusing on aspects that were only marginally impacted by the strategic turn. Saved!

Not afraid of moving targets

The example reveals that, unlike Mr. Emmons, businesses face targets that move. In some cases, the targets can even seem to go in any direction at any moment. But if you come well-prepared with a solid business case, there’s nothing to be afraid of.

Do you need advice on how to develop your supply chain transformation business case?

Steven Depue

Advisory Manager at OMP BE

Biography

With a background in management consulting and technology implementations, Steven delivers strategic and operational planning advice and customized solutions to meet the supply chain challenges faced by customers worldwide.