How consumer goods leaders are successfully making planning cycles shorter

Dirk Van Ginderachter - November 15, 2020

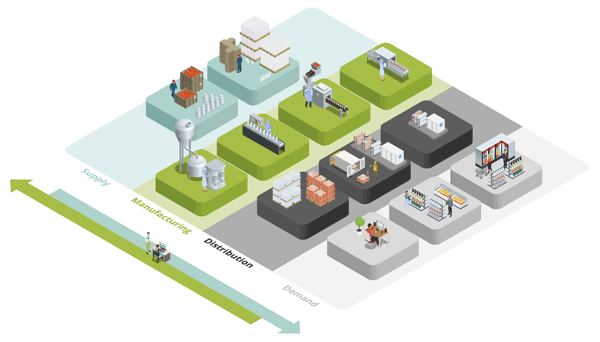

An increasing number of consumer goods companies are engaging in efforts to make planning cycles much shorter. But this ambitious undertaking comes with a great many challenges, obliging companies to redefine their planning cycles as well as the systems they use.

At the beginning of the COVID-19 crisis, we all saw how it took the industry nearly two weeks to replenish grocery store shelves with products such as toilet paper, pasta and canned tomatoes, which had been the subject of customer stockpiling. The delay wasn’t by chance. These products have an average 10-day lead time, of which a significant part is due to the planning cycle running over a full week.

Toward a more responsive supply process

Blog post

The good news is that CPG leaders are investing to dramatically shorten lead times, putting in place new production equipment to allow quicker changeovers and make production schedules more dynamic. This also paves the way for a much more responsive supply process.

The ambition is to move from a weekly to a daily supply planning cycle and, in some cases, even to one cycle per shop floor shift. This is a major change, leading companies to reorganize their planning organizations completely. We are seeing CPG leaders dissolve their local planning teams in favor of centralized planning service centers, put in place to devise and optimize production schedules and distribution and deployment plans over multiple manufacturing sites in different parts of the world.

Blog post

Don’t waste your time or money

The new reality provides the perfect opportunity to align and further strengthen planning practices. However, it also means that planning systems have to be much more tightly integrated. Historically, consumer goods companies have used a whole range of best-of-breed solutions to plan ordering, production and distribution. While this can work in weekly cycles, it becomes almost impossible when you have a new schedule every day or for each shift.

As the distribution plan is created, production constraints should be apparent in real time, and smart solvers should be in place to rapidly balance these constraints. There’s simply no time to align different planners across the value chain, and no money to be wasted on suboptimal plans.

One process, one solution

Blog post

CPG leaders understand this. They put in place one single fully integrated planning solution and one comprehensive planning process, with how-to knowledge relating to specific shop floors integrated within this unified solution.

Planners are being trained to understand the operational strategies in use in each plant they serve. And solver techniques are being integrated and configured to make sure that plans are optimized from a company-wide and value stream perspective, eliminating any subjective bias.

Blog post

Maintaining effective communication lines

We should be aware, however, that pulling planners away from manufacturing units could have its downside too. One concern is that the plan must always be in tune with what happens on the shop floor. We are seeing efforts to strengthen lines of communication between planning hub and plant so that valuable experience from the plants is captured. Agreements define how trade-offs should be made when there are conflicting priorities, and daily video conferences review any deviation.

Want to learn how CPG companies manage to make their planning cycle shorter? Get in touch.

Dirk Van Ginderachter

Director at OMP BE

Biography

With 15 years at OMP, Dirk currently works on business development and customer implementation in the life sciences and consumer goods industries, focusing on helping to achieve healthy communities and meeting the needs and aspirations of consumers.