The new planning edge for tire manufacturers

Introducing Unison Planning™ for Tires: the planning solution tailored to the global tire industry. It delivers real benefits:

- Planning keeps pace with changing demand, ensuring tires are available to vehicle assembly plants as well as to wholesalers.

- Asset utilization is maximized, allocating the available manufacturing capacity for maximum efficiency and service.

- Multi‑stage batch manufacturing is fully controlled, ensuring product compliance, optimizing batch sizes, and minimizing setup times.

- Raw material intake and preparation of semi-finished products are optimized for the end-to-end manufacturing flow

- Supply to distribution centers is optimized with full-carrier loads.

How does Unison Planning™ for Tires work?

Based on a digital twin of your entire supply chain (including demand, sourcing, manufacturing, and distribution), it provides full end‑to‑end visibility across tactical and operational layers, with comprehensive S&OP functionality that allows tactical shifts of production volumes within and between plants. Its integrated campaign and multi‑stage batch planning optimizes batch sizes and reduces setups. Its transport planning incorporates truck‑load optimization for distribution.

Science‑based forecasting

State‑of‑the‑art demand sensing and machine learning techniques turn real‑world data into short‑term demand predictions, reducing the lag and inaccuracy of traditional forecasting. By ingesting daily or weekly data such as POS records, OEM orders, and external factors like expected weather and economic trends, crucial insights are generated to improve and accelerate decisions regarding manufacturing and inventory buildup.

Optimized, end‑to‑end inventory

Meeting customer demand with the right products in the right place requires a subtle balance between service level, inventory, and transportation cost. Unison Planning’s multi‑echelon inventory optimization (MEIO) helps the industry reduce volatility and stock levels across the supply network.

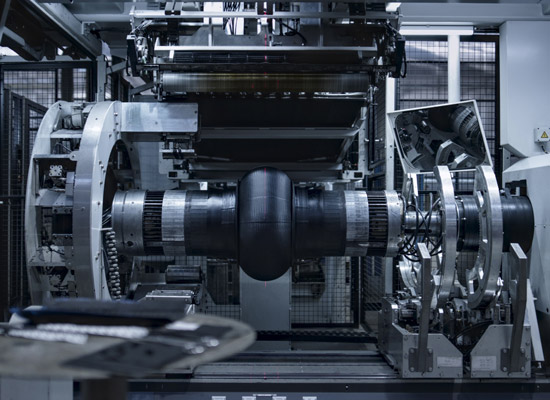

The critical manufacturing steps of tire building and curing are optimized at the machine group level to maximize mold usage and reduce mold change-overs. Fabric, steel belt, bead, tread, sidewall, and innerliner manufacturing are planned in parallel, taking into account forecasted demand, manufacturing efficiency, and the need to keep inventory levels as low as possible. Part of the upstream activities can be planned in campaigns to improve manufacturing efficiency.

Integrated distribution planning ensures that trucks are loaded to full capacity, travel distances are minimized, and products are available at the right place and the right time in the multi-tiered distribution network.

Decision‑centric planning

Forecasted demand can be prioritized in line with your business strategy, using rules such as 100% service levels to OEM assembly lines and on-the-shelf availability of high‑runners at wholesalers. Planners can easily create and run multiple simulations to evaluate the potential benefits and drawbacks of plan changes. Simulations may be triggered by market events or run proactively to continuously improve strategies and tactics and to prepare for possible scenarios. They can also be used to optimize the sourcing and manufacturing networks in response to expected demand shifts.

If needed, tactical and operational plans can be adjusted ad hoc whenever the business requires a quick response to events. This decision‑centric planning capability is especially relevant in a dynamic geopolitical and economic reality, where tariff changes and other events urge the industry to make agile, bold decisions.

Proven tire industry expertise

The solution is implemented by OMP specialists with deep, hands‑on experience in the tire industry, ensuring relevance and rapid ROI.

So why choose Unison Planning™ for Tires?

- Speed: Faster response to trends and events that cause shifts in demand and product innovation.

- Accuracy: Forecast errors shrink thanks to real-world data capture and demand sensing.

- Efficiency: Forecast errors shrink thanks to real-world data capture and demand sensing.

- Profitability: Margins improve as efficiency increases and service levels rise in both the OEM and replacement tire markets.

- Quality and sustainability: Quality, durability, and sustainability goals are baked into every plan.

Looking for real business results? Maximize service levels and profits with Unison Planning™ for Tires.

Success stories

What our customers say

“We wanted a solution that was fully integrated – built, engineered and designed that way. That’s where we found OMP.”

Rick Poe, Director of Supply Chain Business Services at Shaw Industries

“Our markets require us to react incredibly fast to changes in demand. Weekly planning cycles are a thing of the past. We’re planning in daily cycles now, or even per shift.”

David Hamer, Supply Planning Manager at P&G

“Unison Planning enables increased agility and synchronization. The supply chains of our products are now planned in Unison Planning consistently throughout the day. Its end-to-end approach optimizes the launch planning of new SKUs in our different markets while minimizing remnants on phase-out products and raw materials.”

Harald Fischer, Global Supply Planning Application Manager at Procter & Gamble