How AI-enabled planning systems are changing the game for packaging operations

Jose Guzman and Peter Dobell - February 5

What happens when the next big disruption hits your supply chain? A sudden spike in demand. A supplier delay. An unplanned downtime on critical machinery. Will your planning solution empower you to seize new opportunities and respond to disruptions… or hold you back?

The packaging industry is entering a new era where agility is no longer optional, it’s expected.

Traditional planning tools, built on static rules with periodic replanning and manual intervention, can no longer keep pace with today’s operational demands. Advanced supply chain planning has therefore become a core layer of plant infrastructure, with AI transforming how decisions are made across the operation.

This shift requires more than adding AI features to existing planning tools. It calls for a fundamentally different approach, where AI is embedded directly into planning workflows and AI agents continuously support decisions as conditions change.

Blog post

UnisonIQ: orchestrating decisions with agentic AI

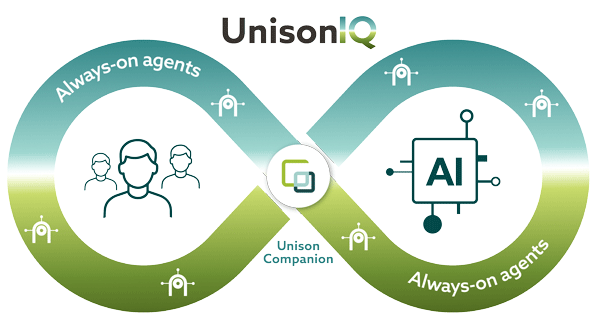

As the newest evolution of OMP’s Unison Planning™ for Packaging solution, UnisonIQ is a breakthrough AI orchestration framework that embeds agentic AI directly into the planning environment.

'Agents' refer to AI that continuously monitors plans and proposes actions as conditions change, with planners guiding decisions. Designed specifically for the realities of the packaging industry, it builds on OMP’s long-standing role in supporting packaging companies to enable smarter, faster decision-making.

Blog post

“UnisonIQ brings together decades of supply chain expertise with agentic AI to help planners move from reactive responses to confident, value-adding autonomous decisions.”

By embedding agentic AI into the planning environment, UnisonIQ elevates supply chain planning from a static coordination function to an active decision backbone for the plant. This shift becomes tangible in day-to-day planning workflows, where agentic AI directly supports decision-making in dynamic operating conditions.

Blog post

Natural language interaction with generative AI

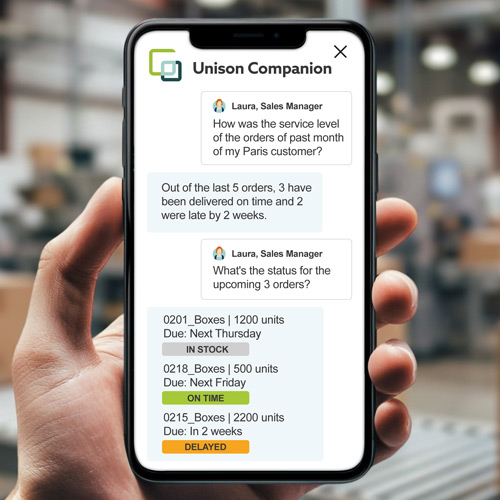

Generative AI, powered by OMP’s Unison Companion, further enhances this experience by enabling planners to interact with the planning system through natural language.

Instead of searching documentation or relying on informal knowledge, they can ask practical, day-to-day questions such as which paper grades to order according to current demand, what’s changed in the plan since yesterday, or why a particular order is at risk. This approach shortens onboarding and improves adoption across planning and operational roles.

Blog post

Expanding decision context for smarter planning decisions

Planning decisions rarely depend on numbers alone. Emails, plan comments, documents, and external signals often contain critical context. By connecting these sources to the planning environment, planners gain clearer insight into what is happening and why, helping teams prioritize issues and respond faster to disruptions without leaving the planning workflow.

Proven in the packaging industry: trusted by global leaders

These capabilities are already in use across the packaging industry. Global leaders such as Smurfit Westrock, Mondi, and IP - DS Smith rely on OMP’s Unison Planning™ for Packaging to support complex, high-volume operations at scale.

Will you lead in the agentic age?

Agentic AI has moved beyond theory. Through platforms like UnisonIQ, it is already reshaping how supply chain decisions are made, enabling autonomous decision-making built on human–AI synergy. Will you lead in the agentic age? Or wait for it to happen to you?

Discover how UnisonIQ embeds agentic AI to advance supply chain planning for packaging.

Jose Guzman

Commercial Lead Paper, Plastics & Packaging at OMP USA

Biography

Jose has been connecting with OMP customers since 2013, achieving highly productive supply chain outcomes. He is passionate about creating long-term partnerships, leveraging great ideas, problem-solving skills, and the power of transformational technologies.

Peter Dobell

Senior Business Development Paper, Plastics and Packaging

Biography

Peter is a Senior Business Development Leader with over 25 years of experience in the paper, plastics, and packaging industry. He specializes in enabling organizations to rapidly drive growth through adoption of advanced supply chain planning solutions.